25-50kg automatic bag slitting machine, bag slitting system,automatic bag emptying machine

Product description:

Working principle:

Automatic bag slitting machine is mainly composed of belt conveyor and main machine. The main machine is composed of base, cutter box, drum screen, screw conveyor, waste bag collector and dust removal device.

The bagged materials are transported to the slide plate by the belt conveyor, and slide along the slide plate by gravity. During the sliding process, the packaging bag is cut by fast rotating blades, and the cut residual bags and materials slide into the drum screen for screening. The materials dropped from the drum screen are output by screw conveyor, and the damaged packaging bags, impurities and caking materials are taken out of the body by the drum screen. The dust caused in the process of cutting knife breaking bag is collected by bag filter and shaken into screw conveyor through pulse control system (the materials output from screw conveyor can be transported to material storage tank by pipe chain conveyor or pneumatic conveying device).

Video:

Applicable materials:

Technical Parameter:

MoC – Available in mild steel construction with optional coatings & stainless steel with optional finishes.

Capacity: 100 to 800 bags/hour of 25 to 50 kg.

Type of bags: Except Jute made, all other material bags

Material Retention: 1% maximum

Machine Specification:

Bag sizes up to 700mm x 400mm x 145mm (Weight – 50Kgs/bag)

Emptying efficiency – 98% – 99% depending on flowing characteristics of the material

Particle sizes: Powder & pellets of free flow characteristics.

Products pictures:

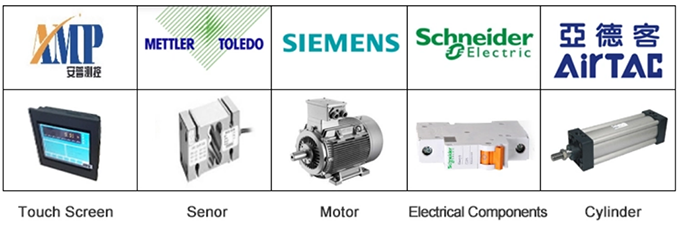

Our Configuration:

Production Line:

Contact:

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatapp:+8613382200234