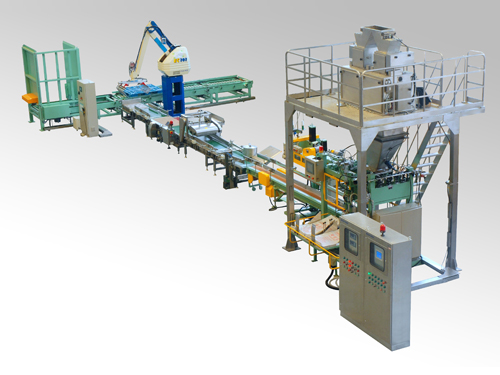

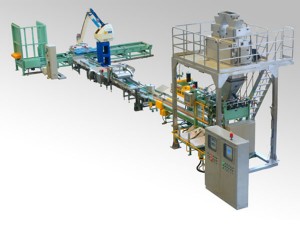

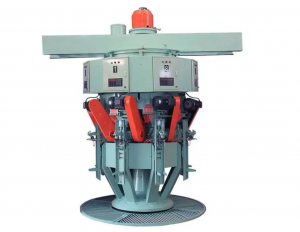

50 Kg Automatic Packing Machine Compost Carousel Auto Bagging Machines

Product Introduction:

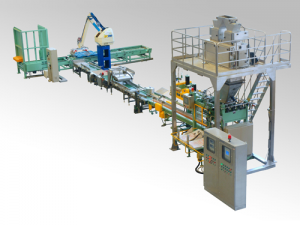

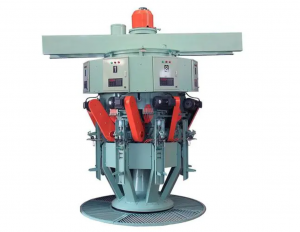

The automated packaging and palletizing system consists of automatic bag feeding system, automatic weighing and packaging system, automatic sewing machine, conveyor, bag reversing mechanism, weight re-checker, metal detector, rejecting machine, pressing and shaping machine, inkjet printer, industrial robot, automatic pallet library, PLC control system and other equipment, which can complete automatic quantitative packaging and palletizing process for granular materials, powder materials.

The automatic line is available for woven bags, PE bags, paper-plastic composite packaging bags, all-paper packaging bags, all-plastic packaging bags and open or valve port packaging bags. It is widely used in food, chemicals, engineering plastics, fertilizer, building materials, pigments, minerals industries. The automatic line has high packaging accuracy, no dust pollution, high degree of automation, and max. palletizing speed of up to 1000 bag / Hour or more.

Technical parameters

1. Material : powder, granules;

2. Weight range: 20kg-50kg / bag

3. Bag type: Open mouth bag or valve port bag;

4. Capacity: 200-1000 bags / hour;

5. Palletizing process: 8 layers / stack, 5 bags / layer, or according to the customer’s requirements

6. Capacity of pallet library: ≥10 pallets.

Product pictures

Technical Features:

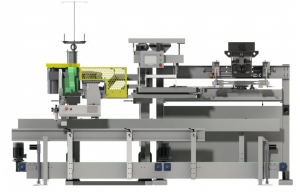

1. The system can be applied to paper bags, woven bags, plastic bags and other packaging materials. It is widely used in chemical industry, feed, grain and other industries.

2. It can be packed in bags of 10kg-20kg, with a maximum capacity of 600 bags/hour.

3. Automatic bag feeding device adapts to high-speed continuous operation.

4. Each executive unit is equipped with control and safety devices to realize automatic and continuous operation.

5. Using SEW motor drive device can bring higher efficiency into play.

6. It is suggested that KS series heat sealing machine should be matched to ensure that the bag mouth is beautiful, leakproof and airtight.

Applicable materials:

Mr. Yark

Whatsapp: +8618020515386

Mr. Alex

Whatsapp:+8613382200234