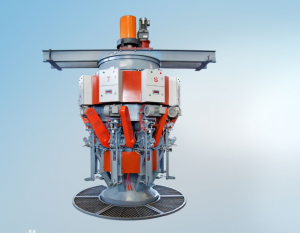

50kg Cement Powder Valve Bags Weighing Filling Machine

Product description:

Valve bagging machine DCS-VBAF is a new type of valve bag filling machine that has accumulated more than ten years of professional experience, digested foreign advanced technology and combined with China’s national conditions. It has a number of patented technologies and has completely independent intellectual property rights. The machine adopts the most advanced low-pressure pulse air-floating conveying technology in the world, and completely uses low-pressure pulse compressed air to uniformly and horizontally convey the material on the ventilating device through a super-abrasion air-floating device with a certain angle, and the material passes through self-adjusting double The stroke gate valve controls the quick feeding and finishing of the material, and the automatic quantitative packaging of the material is completed through the ceramic discharge nozzle and the microcomputer plus the touch screen control. The packaging materials cover a wide range. All powders with a moisture content of less than 5% and a mixture of powder and aggregate (≤5mm) can be automatically packaged, such as industrial micro powder products, powdered pigments, powdered chemical products, flour and food. Additives, as well as ready-to-mix dry mortars (special mortars) of all varieties.

Technical Parameters:

| Weighing range | 20-50kg/bag |

| Packaging speed | 3-6 bags / min (Note: different material packaging speed is different) |

| Measurement accuracy | ± 0.1-0.3% |

| Applicable voltage | AC 220V/50Hz 60W (Or according to the customer’s requirement) |

| Pressure | ≥0.5-0.6Mpa |

| Air consumption | 0.2m3/min Dry compressed air |

| Graduation value | 10g |

| Aggregate in packaging materials | ≤Φ5mm |

| Dust collection air volume | ≥2000m3/h |

| Ceramic nozzle size | Φ63mm (can be adjusted according to customer needs) |

| Valve pocket size | ≥Φ70mm |

| Feed port size | Φ300mm |

| Standard dimensions | 1500mm*550mm*1000mm |

Features:

1. High precision, high speed, long life, good stability, manual bagging, automatic metering.

2. Not subject to the restrictions of packaging containers, suitable for occasions where the variety of materials and packaging specifications change frequently.

3. Designed for vibration feeding and electronic weighing, which overcomes the shortcomings of measurement error caused by the change of material specific gravity.

4. The digital display is simple and intuitive, the packaging specifications are continuously adjustable, the working state is arbitrarily changed, and the operation is very simple.

5. For dusty materials that are easy to produce, we can install the dust-removing interface or vacuum cleaner independently designed by our company.

6. The material contact part is made of stainless steel, which effectively solves the corrosiveness of the material.

7. Its design, less transmission parts, no need to install and maintain the platform bracket.

8. Three-speed feeding mode of adjustable gate, with automatic fast and slow feeding, higher measurement accuracy.

9. There is high-speed metering to improve production efficiency.

Details

Applicable materials

Other auxiliary equipment

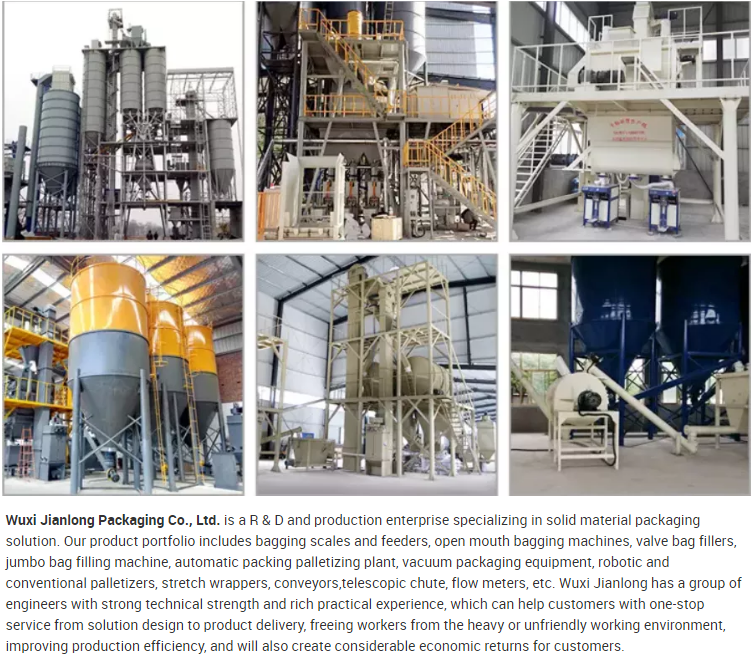

Company profile

Mr. Yark

Whatsapp: +8618020515386

Mr. Alex

Whatsapp:+8613382200234