Auto Feed Bagging Machines Grain Rice Wheat Gravity Feed Bagging Machines

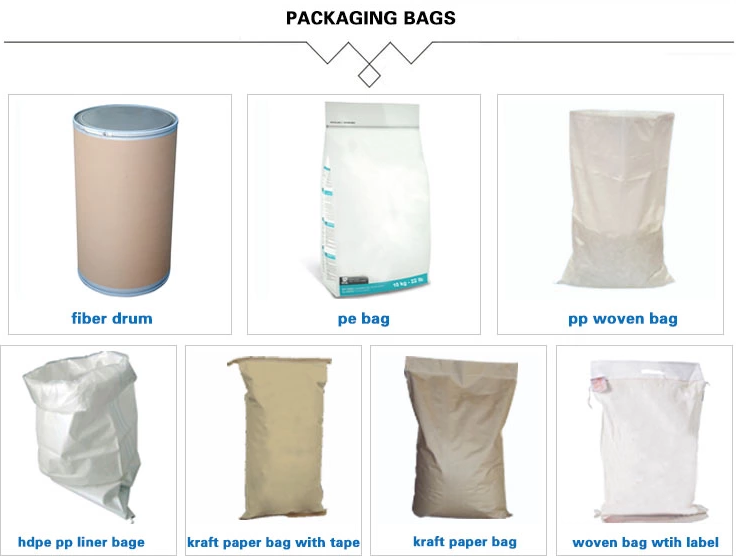

It is suitable for rationing package of the powdery material in the feed, food, grain, chemical industry or particulate material. (For example the grainy material in the mixture, premix material and concentrated material, starch, chemical powder material etc.)

The single scale has one weighing bucket and the double scale has two weighing buckets. The double scales can discharge materials in turn or in parallel. When discharging materials in parallel, the measuring range and error are doubled.

Working principle

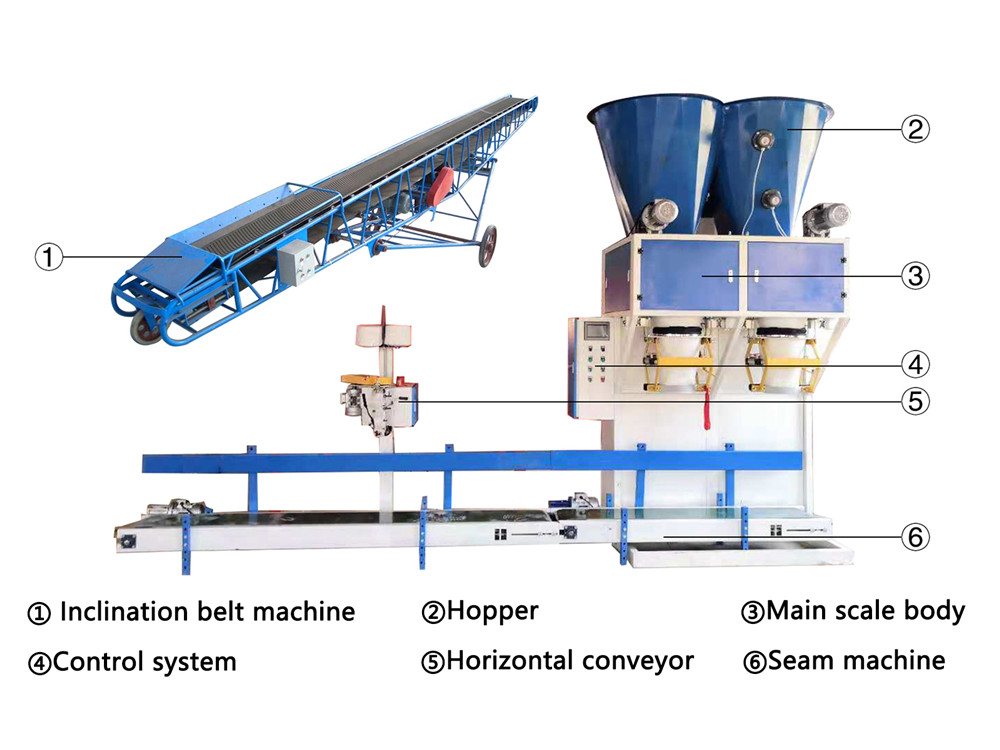

The granule packaging machine with single hopper needs to manually wear the bag, manually put the bag on the discharging spout of the packing machine, toggle the bag clamping switch, and the control system will drive the cylinder after receiving the bag clamping signal to drive the bag clamp to clamp the bag and start feeding at the same time The mechanism sends the material in the silo into the weighing hopper. After reaching the target weight, the feeding mechanism stops feeding, the silo is closed, and the material in the weighing hopper is filled into the packaging bag by gravity feeding. After the filling is completed, the bag clamper will automatically open, and the filled packaging bag will automatically fall onto the conveyor, and the conveyor will be transported back to the sewing machine. The bag will be manually assisted to sew and output to complete the packaging process.

Functional features

1. Manual assistance is needed for bag loading, automatic weighing, bag clamping, filling, automatic conveying and sewing;

2. Gravity feeding mode is adopted to ensure the bagging speed and accuracy through instrument control;

3. It adopts high precision sensor and intelligent weighing controller, with high precision and stable performance;

4. The parts in contact with materials are made of stainless steel with high corrosion resistance;

5. Electrical and pneumatic components are imported components, long service life and high stability;

6. The control cabinet is sealed and suitable for harsh dust environment;

7. Material out of tolerance automatic correction, zero point automatic tracking, overshoot detection and suppression, over and under alarm;

8. Optional automatic sewing function: photoelectric induction automatic sewing after pneumatic thread cutting, saving labor.

Parameters

| Model | DCS-GF | DCS-GF1 | DCS-GF2 |

| Weighing Range | 1-5, 5-10, 10-25, 25-50 Kg/bag, customized needs | ||

| Precisions | ±0.2%FS | ||

| Packing Capacity | 200-300bag/hour | 250-400bag/hour | 500-800bag/hour |

| Power supply | 220V/380V, 50HZ, 1P/3P (Customized) | ||

| Power (KW) | 3.2 | 4 | 6.6 |

| Dimension (LxWxH)mm | 3000x1050x2800 | 3000x1050x3400 | 4000x2200x4570 |

| The size can be customized according to your site. | |||

| Weight | 700kg | 800kg | 1600kg |

The above parameters are only for your reference, the manufacturer reserves the right to modify the parameters with the development of the technology.

Working principle

The granule packaging machine with single hopper needs to manually wear the bag, manually put the bag on the discharging spout of the packing machine, toggle the bag clamping switch, and the control system will drive the cylinder after receiving the bag clamping signal to drive the bag clamp to clamp the bag and start feeding at the same time The mechanism sends the material in the silo into the weighing hopper. After reaching the target weight, the feeding mechanism stops feeding, the silo is closed, and the material in the weighing hopper is filled into the packaging bag by gravity feeding. After the filling is completed, the bag clamper will automatically open, and the filled packaging bag will automatically fall onto the conveyor, and the conveyor will be transported back to the sewing machine. The bag will be manually assisted to sew and output to complete the packaging process.

Functional features

1. Manual assistance is needed for bag loading, automatic weighing, bag clamping, filling, automatic conveying and sewing;

2. Gravity feeding mode is adopted to ensure the bagging speed and accuracy through instrument control;

3. It adopts high precision sensor and intelligent weighing controller, with high precision and stable performance;

4. The parts in contact with materials are made of stainless steel with high corrosion resistance;

5. Electrical and pneumatic components are imported components, long service life and high stability;

6. The control cabinet is sealed and suitable for harsh dust environment;

7. Material out of tolerance automatic correction, zero point automatic tracking, overshoot detection and suppression, over and under alarm;

8. Optional automatic sewing function: photoelectric induction automatic sewing after pneumatic thread cutting, saving labor.

Parameters

|

Model |

DCS-GF |

DCS-GF1 |

DCS-GF2 |

|

Weighing Range |

1-5, 5-10, 10-25, 25-50 Kg/bag, customized needs |

||

|

Precisions |

±0.2%FS |

||

|

Packing Capacity |

200-300bag/hour |

250-400bag/hour |

500-800bag/hour |

|

Power supply |

220V/380V, 50HZ, 1P/3P (Customized) |

||

|

Power (KW) |

3.2 |

4 |

6.6 |

|

Dimension (LxWxH)mm |

3000x1050x2800 |

3000x1050x3400 |

4000x2200x4570 |

|

The size can be customized according to your site. |

|||

|

Weight |

700kg |

800kg |

1600 |

The above parameters are only for your reference, the manufacturer reserves the right to modify the parameters with the development of the technology.

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatsapp:+8613382200234