Automaiic valve bagging system, valve bag automatic bagging machine, automatic valve bag filler

Product description:

Automaiic valve bagging system includes automatic bag library, bag manipulator, recheck sealing device and other parts, which automatically completes the bag loading from the valve bag to the valve bag packing machine. Manually place a stack of bags on the automatic bag library, which will deliver a stack of bags to the bag picking area. When the bags in the area are used up, the automatic bag warehouse will deliver the next stack of bags to the picking area. When it is detected that the bags in the bag library are about to be used up, the automatic alarm will remind the staff on site to supplement the bags.

The bag manipulator will pick up, open and cover the bag automatically. When the previous bag is being packed, the bag manipulator will pick up and open the next bag and wait.

After packaging, the package is pushed to the conveying system through the bag pushing device.

The control system is responsible for interlocking control of each unit equipment, and has perfect fault protection and interlocking stop function with upstream and downstream. It adopts PLC automatic control, and has the following functions:

1. In case of bag shortage in bag library, automatic alarm will be given;

2. In place detection of the bag, if there is a bag fault, automatic fault handling;

3. Packaging bag transportation in place detection;

4. The bag mouth cleaning system, the air blowing small mouth is automatically inserted into the small mouth of the packaging bag, and the back end of the small mouth is clamped, the dust at the bag mouth is cleaned through the air blowing small mouth and then exits, and the dust is sucked away through the dust removal system;

5. The whole operating system is easy to use and easy to repair and maintain.

Video:

Applicable materials:

Technical Parameter:

1. Packing bag form: valve port packing bag;

2. Speed: 150-180 packets / hour;

3. Positive pressure gas source: 0.6-0.7mpa;

4. Suction bag negative pressure gas source: – 0.04 ~ -0.06mpa;

5. Power supply: AC380V, 50Hz;

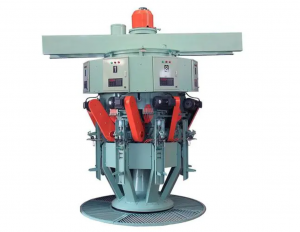

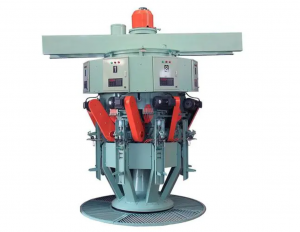

Products pictures:

Our Configuration:

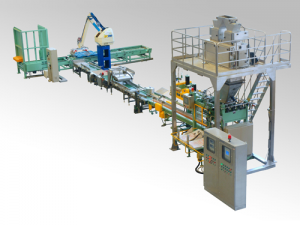

Production Line:

Contact:

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatapp:+8613382200234