Automatic 40kg Bag Kraft Paper Bag Stacker Machine Auto Palletizer

Product overview

Low-Level and High-Level Palletizers

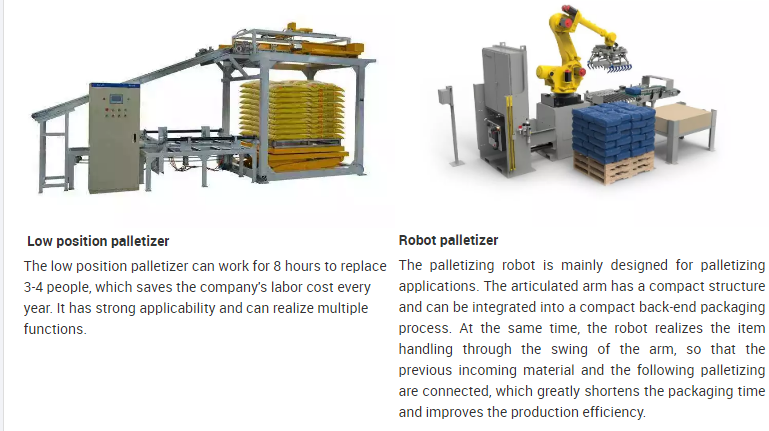

Both types work with conveyors and a feed area that receives products. The difference between the two is that low-level load products from the ground level and high-level load products from above. In both cases, products and packages arrive on conveyors, where they are continuously transferred to and sorted on the pallets. These palletizing processes may be automatic or semi-automatic, but either way, both are faster than the robotic palletizing process.

High position palletizer is used behind the packaging scale. In front of the palletizer, it can be equipped with bagging machine, boxing machine, sealing machine, fully automatic bagging machine, metal detector, weight recheck and other equipment.

The main components of the automatic palletizer are: Summary conveyor, climbing conveyor, indexing machine, marshalling machine, layering machine, elevator, pallet warehouse, pallet conveyor, pallet conveyor and elevated platform, etc.

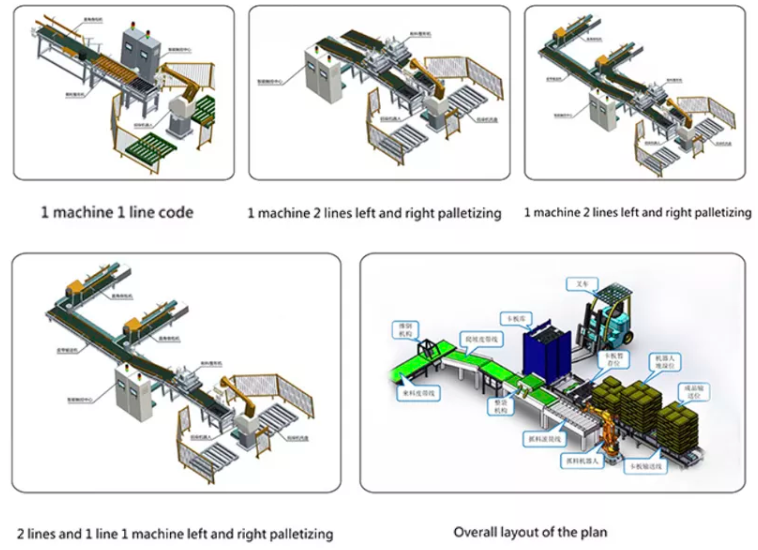

Automatic Palletizing Production Line Common Plan

Advantages of high-level automatic bag palletizer machine

1. High level automatic palletizer adopts linear coding, with fast palletizing speed.

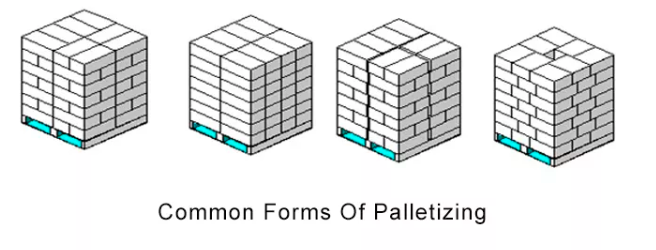

2. The bag palletizer robot adopts servo coding mechanism to achieve any palletizing type, which is suitable for the characteristics of many bag types and various coding types. The servo bag dividing mechanism is smooth, reliable and does not impact on the bag body, which can protect the appearance of the bag body to the maximum.

3. The bag turning of the automatic packaging palletizer is realized by the servo steering machine, compared with the bag stopper turning, it will not cause impact on the bag body and will not damage the appearance of the bag body.

4. Intelligent servo palletizer palletizer has low power consumption, fast speed and beautiful palletizing type to save operation cost

5.The cement palletizing robot adopts heavy pressure or vibrating leveler to squeeze or vibrate the bag body smoothly, shaping effect

6. High level depalletizer can adapt to multiple bag types and multiple code types, and the change speed is fast (within 10 minutes to complete the production variety change)

Technical parameters

| Item | Content |

| Product Name | Single Station palletizer |

| Weighing Range | 10kg/20kg/25kg/50kg |

| Packing Speed | 400-500 packs/hour |

| Power | AC380V +/- 10% 50HZ or customized |

| Air pressure requirement | 0.6-0.8 Mpa |

| Host size | L3200*W2400*H3000mm |

| Number of layers | 1-10 or customized |

Application

Fertilizer, feed, flour, rice, plastic bags, seeds, laundry detergent, cement, dry mortar, talcum powder, poly slag agent and other big bag products.

Related machines

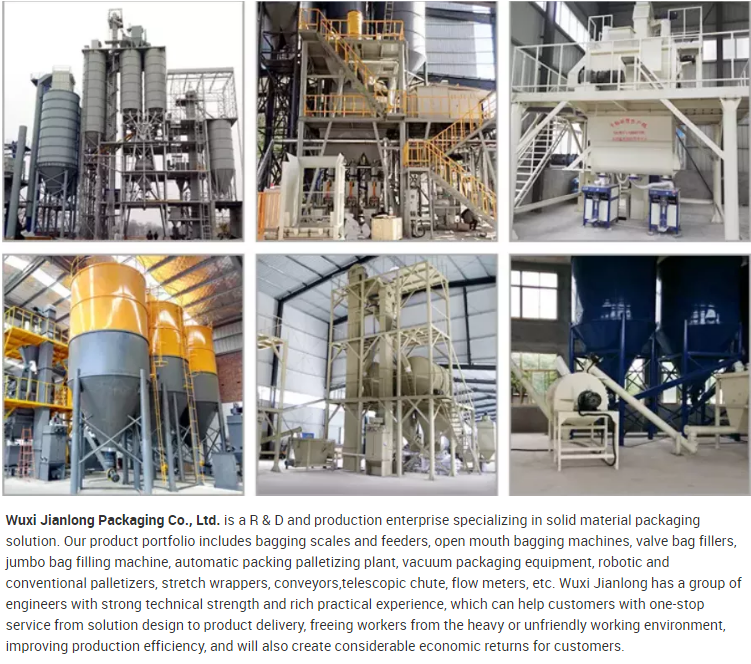

Company Profile

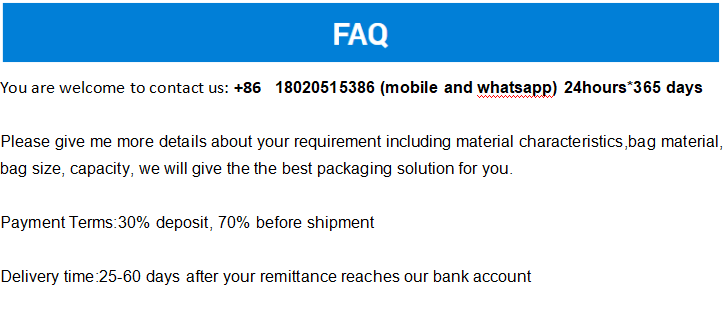

Mr. Yark

Whatsapp: +8618020515386

Mr. Alex

Whatsapp:+8613382200234