Automatic sand bag filling machine for sale

What is a sand bag filling machine?

Sand filling machines are industrial automation equipment specifically designed for quickly and efficiently filling bulk materials such as sand, gravel, soil, and mulch into bags. These machines are widely used in construction, agriculture, gardening, and emergency flood preparedness to meet the needs of rapid packaging and distribution of bulk materials.

What is the structure and the working principle of a sand bag filling machine?

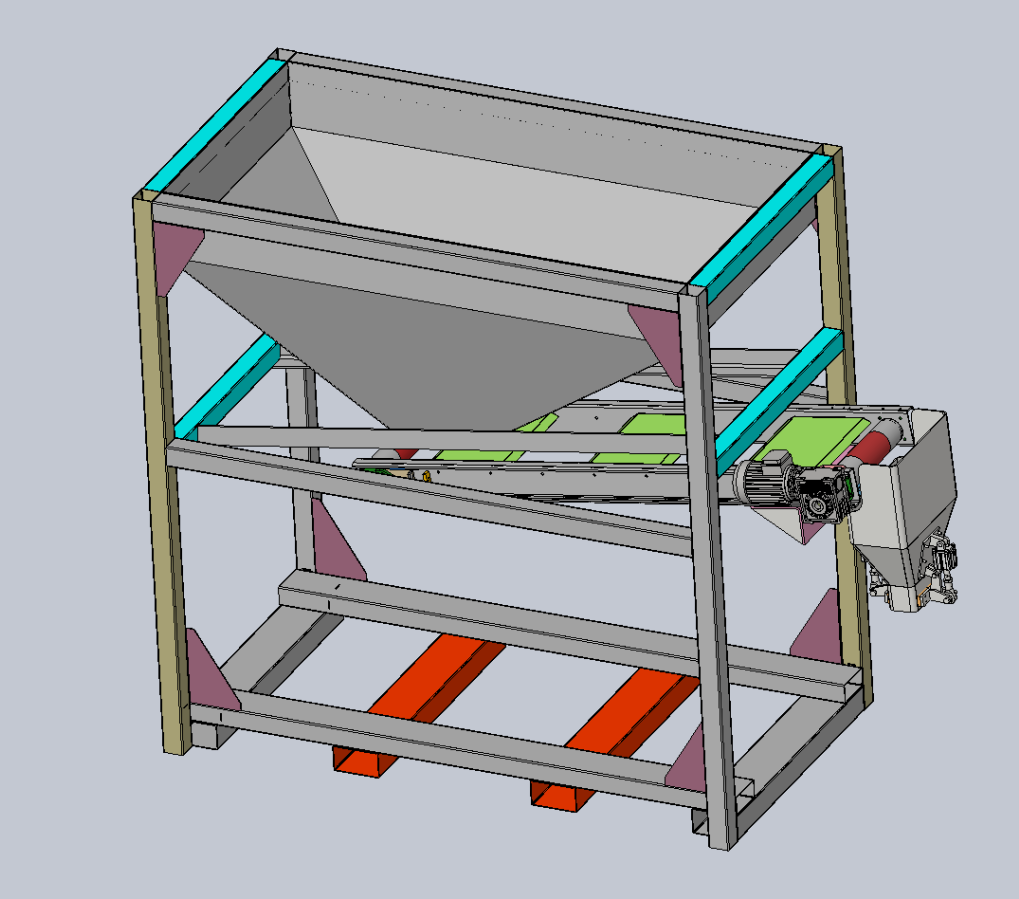

The sand bag filling machine is mainly composed of a hopper, two belt conveyors, a weighing controller, a bag sewing machine, etc. The loader feeds the material into the hopper evenly, and then conveys the material to the receiving hopper through the conveyor belt 1. The weighing system is used to weigh the material until the preset target value, and the bag automatically falls on the belt conveyor ,then the filled he bag is transported to the bag sewing machine by the belt conveyor, and the bag is manually assisted in sewing. After sewing, it is then conveyed out by the conveyor.

Technical Parameter:

Type:DCS-BF

Weighting Range:10-50 kg/bag.

Precisions:±0.2%FS to ±5%FS (Depends on material characteristics)

Output Capacity: 300-500 bags/hour

Power Source: 380V/50Hz/3 phase, or customized

Air resource:0.4~0.6 Mpa

Reference Weight: about 400kg

Belt conveyor Dimension: 3000*400mm PVC belt, subject to the real machine

Construction Material:made of carbon steel

How does a sand bag filling machine work ?

Manual Bag placing→Automatic filling→ Automatic weighing→ Auto bag unloading →Automatic bag conveyer → bag sewing (or bag hot sealing)

what materials can it pack ?

Sand (wet or dry)

Soil (screened or native)

Mulch or Compost

Gravel or Stone

Lava Rock or Cinder

Salt and Minerals

Plastic pellet

Wood Chips

Coal

Charcoal

Vegetables include onions, potatoes, sweet potatoes, etc.

Except for powder, it can pack almost all granular materials and block materials less than 15cm.

Bag types:

pre-formed open mouth bags, stand up pouches, or doypacks constructed of paper, plastic, or poly-woven materials

Option:

Air Compressor

Power:2.2KW

Rated pressure:0.7Mpa

Rotation speed:2200R/min

Nominal Volume Flow:200L/min

Capacity of air tank:40L

Weight:35KG

Diesel generator

Cooling mode:Wind cooling

Starting method: Electric start

Rotation speed:3000/3600RPM

Engine oil capacity:1.6L

Diesel capacity:14L

Voltage:220V

Frequency:50Hz/60Hz

Rated power:9KW

Max power:10KW

Voltage fluctuations:±5%

Working temperature≦40°C

Power Factor:0.8

Insulation class:F

DC voltage:12V

DC:8.3A

What is the features of a sand bag filling machine

High Efficiency: Sand bagging machines can fill sandbags upto 500 bag/hour. greatly reducing the time and labor required for manual filling.

Adjustable Filling Capacity: The machines usually come with an adjustable filling weight function, allowing for the filling of bags with different weights according to needs.

Suitable for Various Materials: In addition to sand, these machines can also handle wet sand, gravel, compost, mulch, volcanic rock, and other challenging materials.

Emergency Response: In the case of floods and other emergencies, sand bagging machines can quickly fill and distribute sandbags, which is crucial for flood control and emergency response.