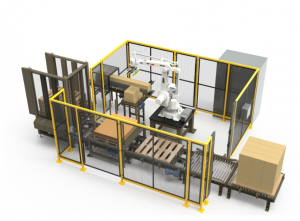

Automatic Tin Can Palletizer Palletizing Machine

Introduction

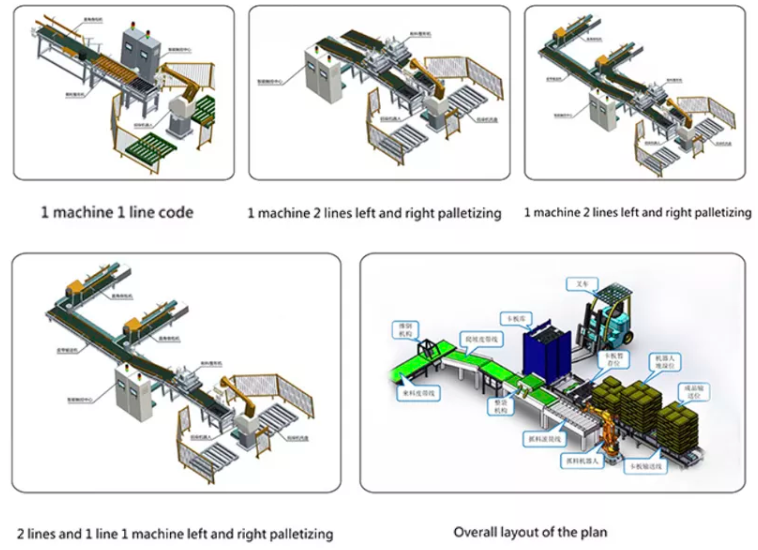

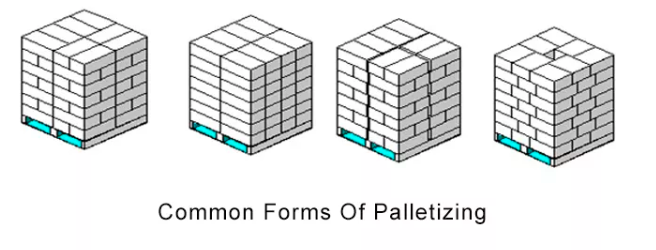

According to a certain order, palletizer stacks the packed products (in box, bag, bucket) to the corresponding empty pallets through a series of mechanical actions so as to facilitate handling and transporting batches of products to improve production efficiency. Meanwhile it can use stack layer pad to improve the stability of each stack layer. Various forms designed to meet different palletizing requirements.

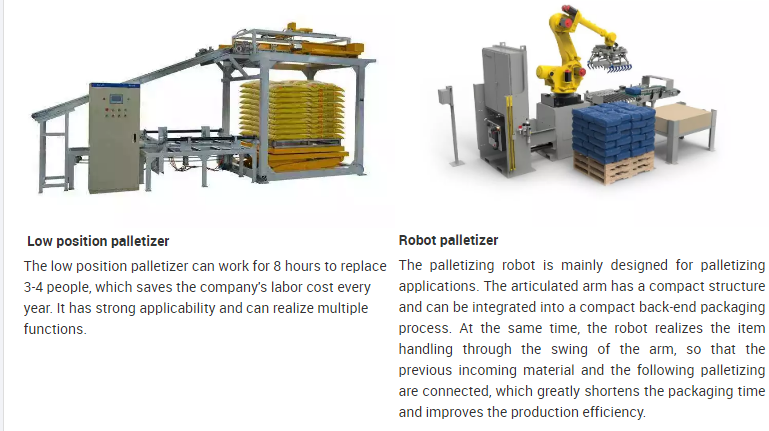

Low-Level and High-Level Palletizers

Both types work with conveyors and a feed area that receives products. The difference between the two is that low-level load products from the ground level and high-level load products from above. In both cases, products and packages arrive on conveyors, where they are continuously transferred to and sorted on the pallets. These palletizing processes may be automatic or semi-automatic, but either way, both are faster than the robotic palletizing process.

The low position palletizer can work for 8 hours to replace 3-4 people, which saves the company’s labor cost every year. It has strong applicability and can realize multiple functions. It can encode and decode multiple lines on the production line, and the operation is simple. People who have not operated before can get started with simple training. The packaging and palletizing system is small, which is conducive to the layout of the production line in the customer’s factory. The palletizing accuracy is high. Human-computer interaction, program gripper movement can be realized. The palletized goods are strong, which will avoid the collapse phenomenon, and helpful for product transportation and storage.

Technical description:

| Weight range | 20-50kg/bag |

| Palletzing capacity | 300-600bag/hour |

| Palletizing layers | 1-12 layers |

| Air pressure | 0.6-1.0Mpa |

| Power supply | 380V 50HZ three-phase four-wire |

Features of Palletizing Machine

Fully automatic bag palletizer is suitable for palletizing of big bags, such as fertilizer, flour, cement, rice, chemical raw

materials and feed stuffs. The use of touch-screen operation is to achieve man-machine dialogue, which show the production speed, the cause of the malfunction and location, a high degree of automation. It uses PLC programmable bag sorting layer stacking, and pallet supply and discharge can be programmed into the program control. High quality chain with good wear resistance ensures high precision, stable transmission and so on. Imported pneumatic components and cylinders ensures high quality and reliable performance.

Other auxiliary equipment

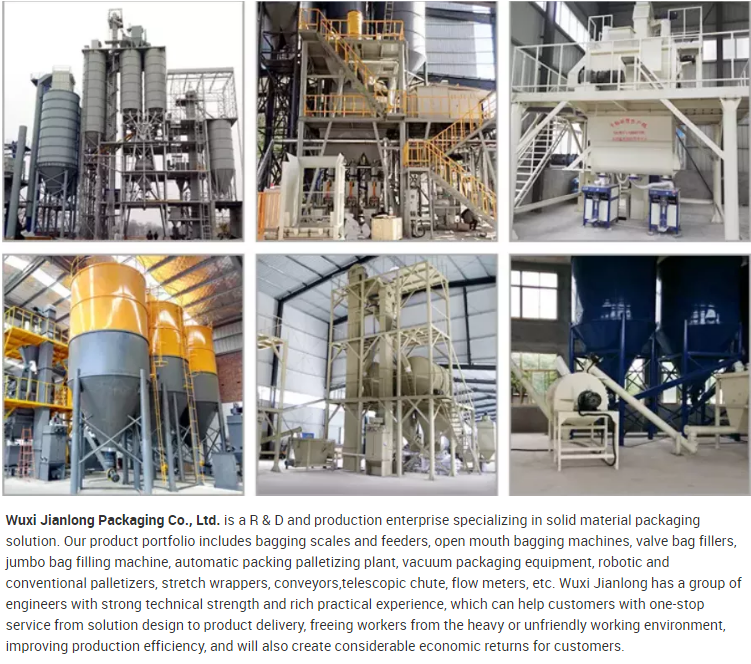

About us

Mr. Yark

Whatsapp: +8618020515386

Mr. Alex

Whatsapp:+8613382200234