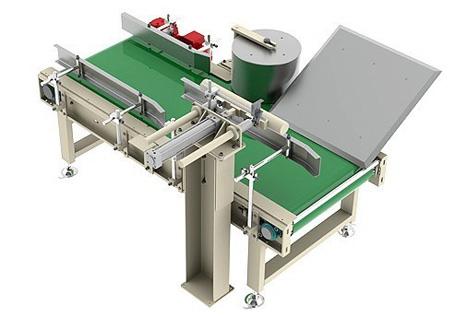

Case Conveyor Reject System Station Belt Weight Sorter Auxiliary Equipment

Application

It is used to check flexible Packaging and rigid packaging products such as Bulk paper bag packaging,Plastic Packaging,Carton packaging,Metal film packaging

Features

The highest checking weight can up to 30kg,Stable working conditions,high speed and accuracy,unqualified products rejected automatically

Mechanical Character

Large weighing range,Belt and roller conveyor

Technical parameters

| Belt conveyor | Herringbone anti-skid belt |

| Bearing | HRB |

| Length | 2500mm |

| Width | 600mm |

| Speed | 26 m/min (to match the speed of the front belt conveyor) |

| Machine frame | Carbon steel |

| Gear motor | AC380V±5% 50Hz , 1.1KW*1 |

| Carbon steel sprayed baffle on both sides of conveyor | Unilateral adjustable width is 0-200 mm and bilateral adjustable width is 0-400 mm. |

About us

Wuxi Jianlong Packaging Co., Ltd. is a R & D and production enterprise specializing in solid material packaging solution. Our product portfolio includes bagging scales and feeders, open mouth bagging machines, valve bag fillers, jumbo bag filling machine, automatic packing palletizing plant, vacuum packaging equipment, robotic and conventional palletizers, stretch wrappers, conveyors,telescopic chute, flow meters, etc. Wuxi Jianlong has a group of engineers with strong technical strength and rich practical experience, which can help customers with one-stop service from solution design to product delivery, freeing workers from the heavy or unfriendly working environment, improving production efficiency, and will also create considerable economic returns for customers.

Wuxi Jianlong offers a wide range of knowledge about packaging machines and related ancillary equipment, bags and products, as well as packaging automation solutions. Through the careful testing of our professional technology and R & D team, we are committed to providing perfect customized solutions for every customer. We combine the international quality with the Chinese local market to provide an ideal automatic / semi-automatic, environmental friendly and efficient automatic packaging system. We are constantly striving to provide customers with intelligent, clean and economical packaging equipment and industrial 4.0 solutions by combining rapid localization service and spare parts delivery.

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatsapp:+8613382200234