Cement Concrete Spouts Rotary Bagging Packaging Equipment

Product description

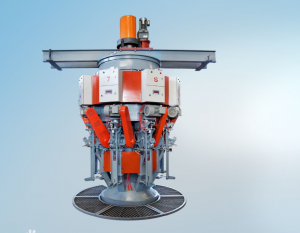

DCS series rotary cement packaging machine is a kind of cement packing machine with multiple filling units, which can quantitatively fill cement or similar powder materials into the valve port bag, and each unit can rotate around the same axis in the horizontal direction.

This machine using frequency conversion speed control of the main rotation system, the center feed rotary structure, mechanical and electrical integrated automatic control mechanism and microcomputer automatic metering device. In addition to manual bag insertion, the equipment can automate the pressing of cement bag, the opening of gate board, the filling of cement and the removal of bag.

In addition, the equipment will not start filling until the bag is inserted properly. And the bag will not drop if the bag weight does not reach the standard value. Bag accidentally falls off the ram automatically closes. Make the equipment operation more simple, more convenient maintenance, to achieve stable performance, accurate measurement, fast discharge speed, good sealing, high efficiency and energy saving characteristics.

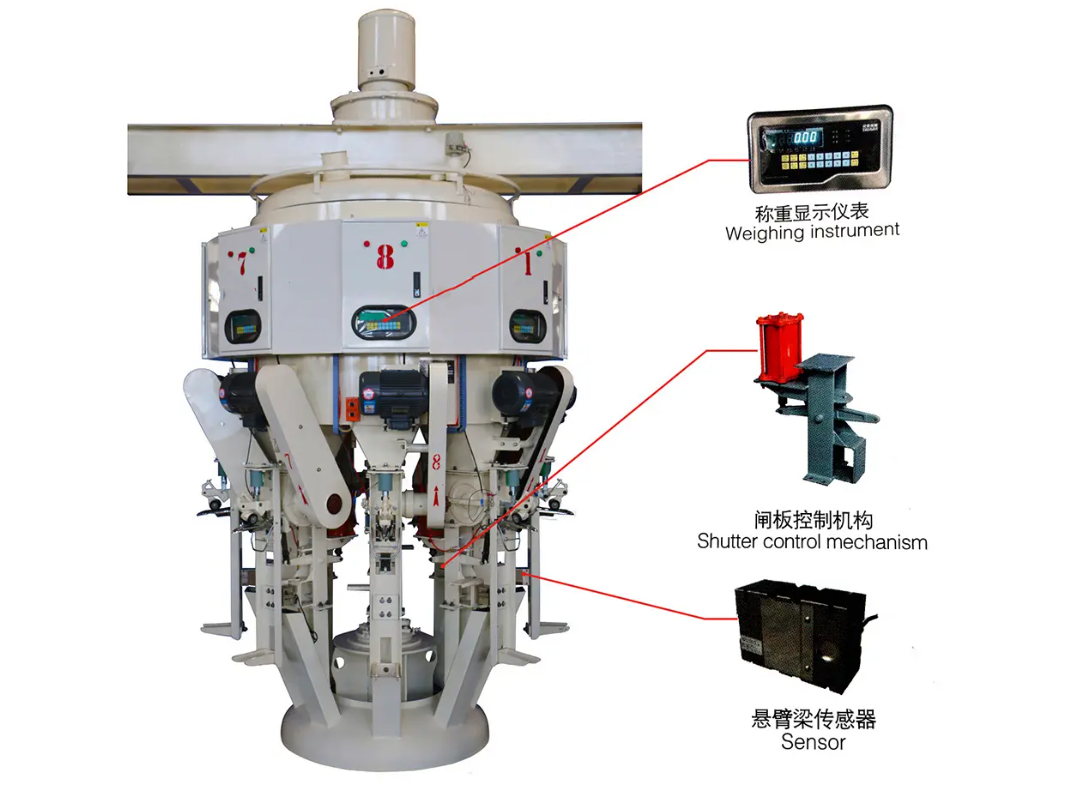

Structure of rotary cement packing machine

Cement packaging machine is mainly composed of machine body, feeding device, material discharging device, control cabinet, microcomputer weighing device and bag hanging device. The fuselage is of welded steel structure with high strength, high rigidity.

1. Feeding device: the cycloidal pinwheel reducer drives the small sprocket, and the chain and large sprocket drive the feeder to rotate to complete blanking.

2. Material discharging device: the motor drives the spindle impeller to rotate, the rotating impeller discharges the cement, and the cement is loaded into the packaging bag through the discharging pipe.

3. Control cabinet: it is started by the travel switch, and the cylinder is controlled by the microcomputer and solenoid valve to open the discharge nozzle and realize the integrated automatic control of electrical appliances.

4. Microcomputer weighing device: the packaging machine adopts microcomputer weighing, which is characterized by convenient adjustment and stable bag weight.

5. Bag dropping device: It has a unique and novel automatic bag dropping device. When the cement is loaded to the rated weight, the discharge nozzle is closed, and the filling is stopped. At the same time, the electromagnet pulls in through the signal of the inductor. The bag pressing device works, and the automatic bag dropping device works. The cement bag falls off, tilts outward, and leaves the packaging machine.

Technical parameters

| Model | Spout | Design Capacity (t/h) | Single Bag Weight (kg) | Rotating Speed (r/min) | Compressed Air Volume (m3/h) | Pressure (Mpa) | Dust Collecting Air Volume (m3/h) |

| DCS-6S | 6 | 70 ~ 90 | 50 | 1.0 ~ 5.0 | 90 ~ 96 | 0.4 ~ 0.6 | 15000 |

| DCS-8S | 8 | 100 ~ 120 | 50 | 1.3 ~ 6.8 | 90 ~ 96 | 0.5 ~ 0.8 | 22000 |

Applicable materials

Quantitative packaging of powder materials with good fluidity such as dry mortar, cement, putty powder, stone powder, fly ash, gypsum powder, heavy calcium powder, quartz sand, fire-fighting materials, etc.

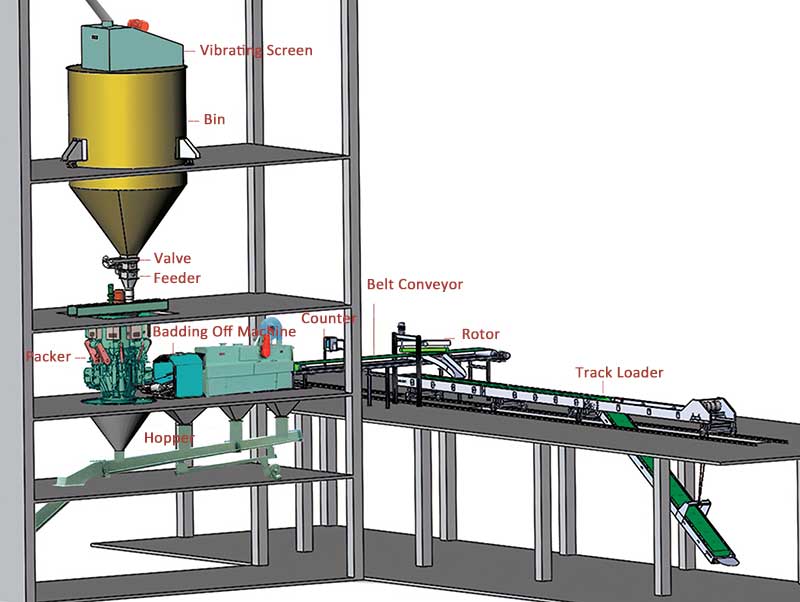

Working principle of cement packaging machine

The cement in the silo enter the cement packing machine’s hopper, and when manually inserting bags, start the travel switch to transmit the signal to the microcomputer, start the solenoid valve, work through the cylinder, open the discharge nozzle, and the high-speed impeller will continuously fill the cement to the material bag through the discharge nozzle. When the bag weight reaches the set value, the sensor will transmit the signal to the microcomputer, and the solenoid valve will start the cylinder through the microcomputer control, Close the discharge nozzle for customized filling; At the same time, the solenoid valve pulls in through the signal of the inductor, and the bag pressing device acts to automatically tilt the bag and drop it. The whole filling process is controlled electrically. Except for manual bag inserting, the opening and closing of cement bag pressing and discharge nozzle; Cement bag filling, weighing and metering, automatic bag dropping and other functions can be completed automatically, so as to reduce mechanical failures and ensure the efficient operation of packaging equipment.

Details

Other projects show

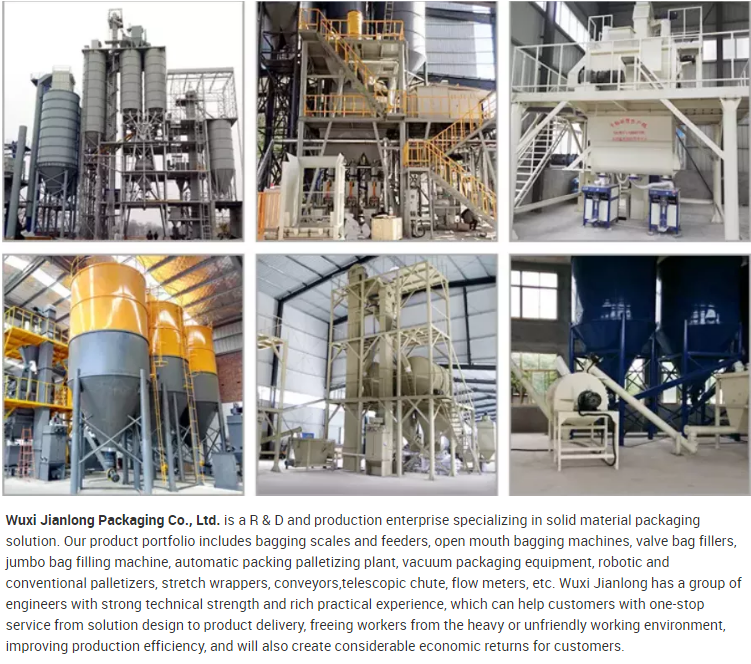

Company profile

Mr. Yark

Whatsapp: +8618020515386

Mr. Alex

Whatsapp:+8613382200234