DCS-BF Mixture bag filler, mixture bagging scale, mixture packaging machine

Product description:

The above parameters are only for your reference, the manufacturer reserves the right to modify the parameters with the development of the technology.

Scope of application: (poor fluidity, high moisture, powdery, flake, block and other irregular materials) briquettes, organic fertilizers, mixtures, premixes, fish meal, extruded materials, secondary powder, caustic soda flakes.

Product introduction and features:

1. DCS-BF mixture bag filler needs manual assistance in bag loading, automatic weighing, bag clamping, automatic filling, automatic conveying and bag sewing.

2. The belt feeding mode is adopted, and the large and small gates are controlled pneumatically so as to achieve the required flow rate.

3. It can solve the problem of some special chemical raw material packaging, which has wide application range and simple operation.

4. It adopts high progress sensor and intelligent weighing controller, with high precision and stable performance.

5. The whole machine is made of stainless steel (except for electrical components and pneumatic components), with high corrosion resistance.

6. Electrical and pneumatic components are imported components, long service life, high stability.

7. The belt feeder adopts anticorrosive belt.

8. Automatic sewing and thread breaking function: photoelectric induction automatic sewing after pneumatic thread cutting, saving labor.

9. Conveyor adjustable lifting: according to different weight, different bag height, conveyor height can be adjusted.

Video:

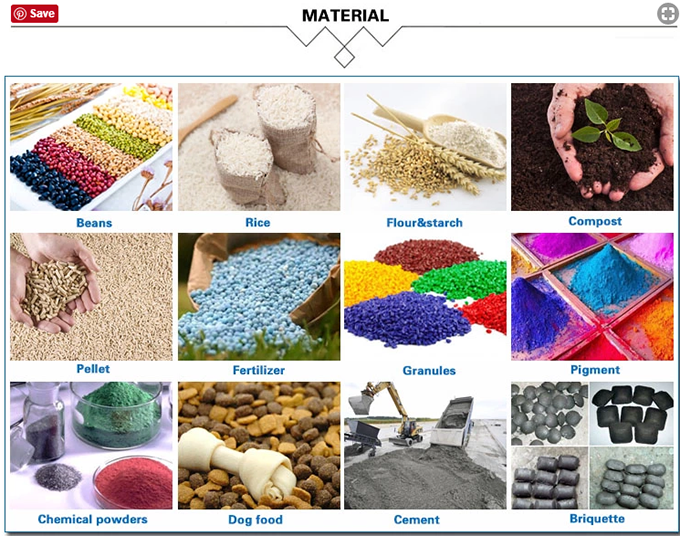

Applicable materials:

Technical Parameter:

| Model | DCS-BF | DCS-BF1 | DCS-BF2 |

| Weighing Range | 1-5, 5-10, 10-25, 25-50 Kg/bag, customized needs | ||

| Precisions | ±0.2%FS | ||

| Packing Capacity | 150-200bag/hour | 180-250bag/hour | 350-500bag/hour |

| Power supply | 220V/380V, 50HZ, 1P/3P ( Customized) | ||

| Power (KW) | 3.2 | 4 | 6.6 |

| Working pressure | 0.4-0.6Mpa | ||

| Weight | 700kg | 800kg | 1500kg |

Products pictures:

Our Configuration:

Production Line:

Contact:

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatapp:+8613382200234