DCS-VSF Fine powder bag filler, Powder auger packer, powder weighing filling machine

Product description:

DCS-VSF Fine powder bag filler is mainly developed and designed for the ultra-fine powder and and it can meet the high-precision packaging requirements. It is suitable for talcum powder, white carbon black, active carbon, putty powder and other ultra-fine powder.

Video:

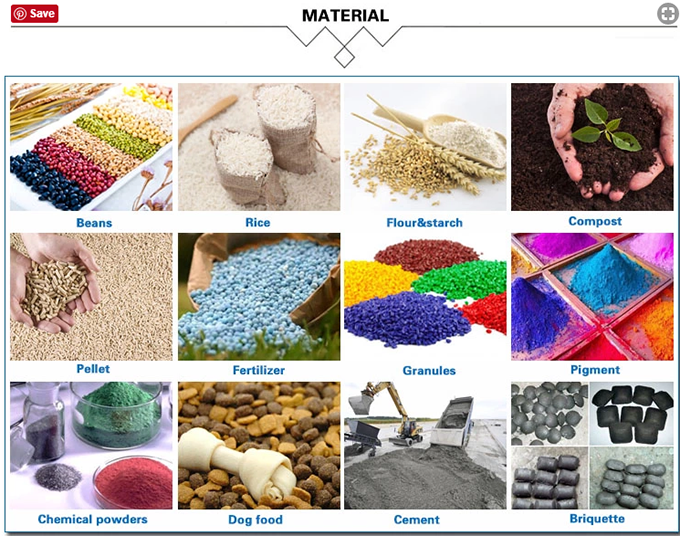

Applicable materials:

Technical Parameter:

Measurement method: vertical screw double speed filling

Filling weight: 10-25kg

Packaging accuracy: ± 0.2%

Filling speed: 1-3 bags / min

Power supply: 380V (three-phase five wire), 50 / 60Hz

Overall power: 4kw

Power supply: AC220V / 380V ± 10%, 50Hz (three-phase five wire)

Air source: clean compressed air, pressure 0.6-0.8mpa, gas consumption 0.2nm3/min

Operating weight: 350kg

Total volume: 1000x850x3300mm or customization

German Siemens PLC and Siemens touch screen control

The weighing sensor adopts METTLER TOLEDO brand, which makes the weighing more accurate

Equipped with dedusting interface

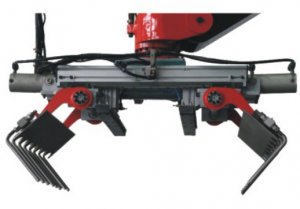

Products pictures:

Our Configuration:

Production Line:

Contact:

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatapp:+8613382200234