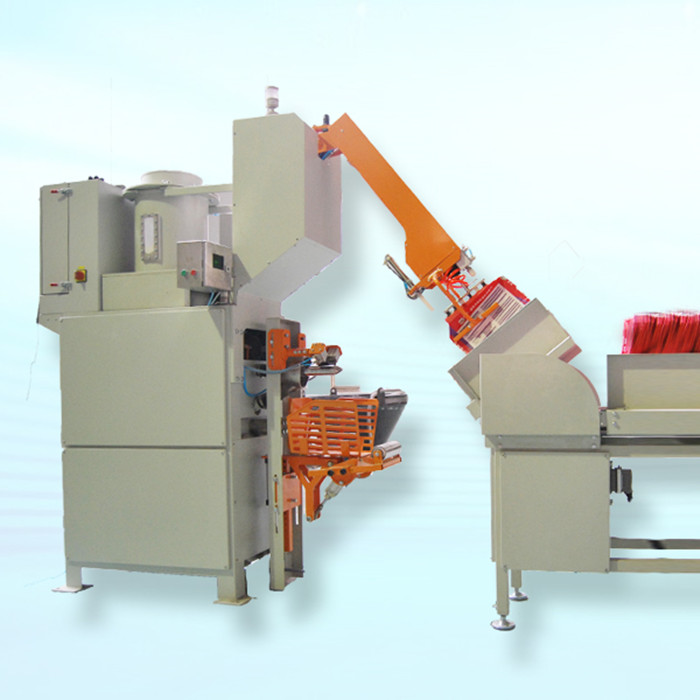

Dry Mortar Valve Bag Filling Machine 50 Kg 25 Kg 40 Kg Impeller Packer

Application and Introduction of Valve Package Machine

Application: Dry powder mortar, putty powder, vitrified micro-beads inorganic thermal insulation mortar, cement, powder coating, stone powder, metal powder and other powder. Granular material, multi-purpose machine, small size and large function.

Introduction: The machine mainly has automatic weighing device. Display the program of setting weight, accumulative package number, working status, etc. The device adopts fast, medium and slow feeding and special feeding auger structure, advanced digital frequency conversion control technology, advanced sampling processing and anti-interference technology, and realizes automatic error compensation and correction to ensure higher weighing accuracy.

Features of Valve Package Machine

1. This machine uses computer metering device, weighing accurate, stable performance, simple operation.

2. The machine is completely sealed and equipped with dust removal port, with reasonable structure and durable, truly realizing environmental protection production.

3. Small size, light weight, convenient adjustment and maintenance.

4. Mechanical and electrical integration, energy saving, the machine can automatically realize the packaging bag pressing, loosening, the gate closing and bag lifting and other functions.

5. Widely use, this machine is not only used for fly ash packaging, but also can be used for other good fluidity powder, particle boring packaging. Dgf-50 series packaging machine mainly has two types of single mouth and double mouth, which can form 4-6 mouth packaging machine.

Parameters

| Applicable materials | powder or granular materials with good fluidity |

| Material feeding method | gravity flow feeding |

| Weighing range | 5 ~ 50kg / bag |

| Packing speed | 150-200 bags / hour |

| Measurement accuracy | ± 0.1% ~ 0.3% (related to material uniformity and packaging speed) |

| Air source | 0.5 ~ 0.7MPa Gas consumption: 0.1m3 / min |

| Power supply | AC380V, 50Hz, 0.2kW |

Details

Mr. Yark

Whatsapp: +8618020515386

Mr. Alex

Whatsapp:+8613382200234