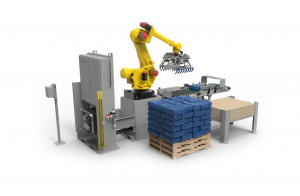

Fluorspar Concentrate Powder Fibc Weighing Baggers For 25kg Tapioca Flour Bag Filling Equipment

Introduction:

The powder packing machine is a machine that integrates mechanical, electrical, optical, and instrumental. It is controlled by a single chip and has functions such as automatic quantitative, automatic filling, and automatic adjustment of measurement errors.

Features:

1. This machine integrates the functions of feeding, weighing, filling, bag-feeding, bag-opening, conveying, sealing/sewing, etc.

2. The machine has good sealing performance and can meet customer’s hygienic requirements.

3. All the electrical components and control components adopt local and foreign well-known brands with reliable performance, such as Siemens PLC and touch screen, Delta converter and servo motor, Schneider and Omron electrical components, etc. Man-machine dialogue platform, both the operator and debugging personnel can set parameters through the touch screen.

DCS-VSFD powder degassing bagging machine is suitable for ultra-fine powders from 100 mesh to 8000 mesh. It can complete the work of degassing, lifting filling measurement, packaging, transmission and so on.

1. The combination of vertical spiral feeding and reverse stirring makes the feeding more stable, and then cooperates with the cone bottom type cutting valve to ensure the controllability of the material during the feeding process.

2. The whole equipment is equipped with an openable silo and quick-release screw assembly, so that the parts of the whole equipment that are in contact with the materials are cleaned, simple and fast, without dead corners.

3. Lifting weighing, combined with screw vacuum degassing and filling device, there is no dust lifting place while ensuring the accuracy of packaging.

4. Touch screen man-machine interface, convenient and intuitive operation, packaging specifications can be adjusted, working status can be switched at any time.

Technical parameters

| Weighing range | 10-25kg / bag |

| Packaging accuracy | ≤± 0.2% |

| Packing speed: 1-3 bags / min | 1-3 bags / min |

| Power supply | 380V, 50 / 60Hz |

| Degassing unit | yes |

| Power | 5KW |

| Weight | 530kg |

Our company

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatsapp:+8613382200234