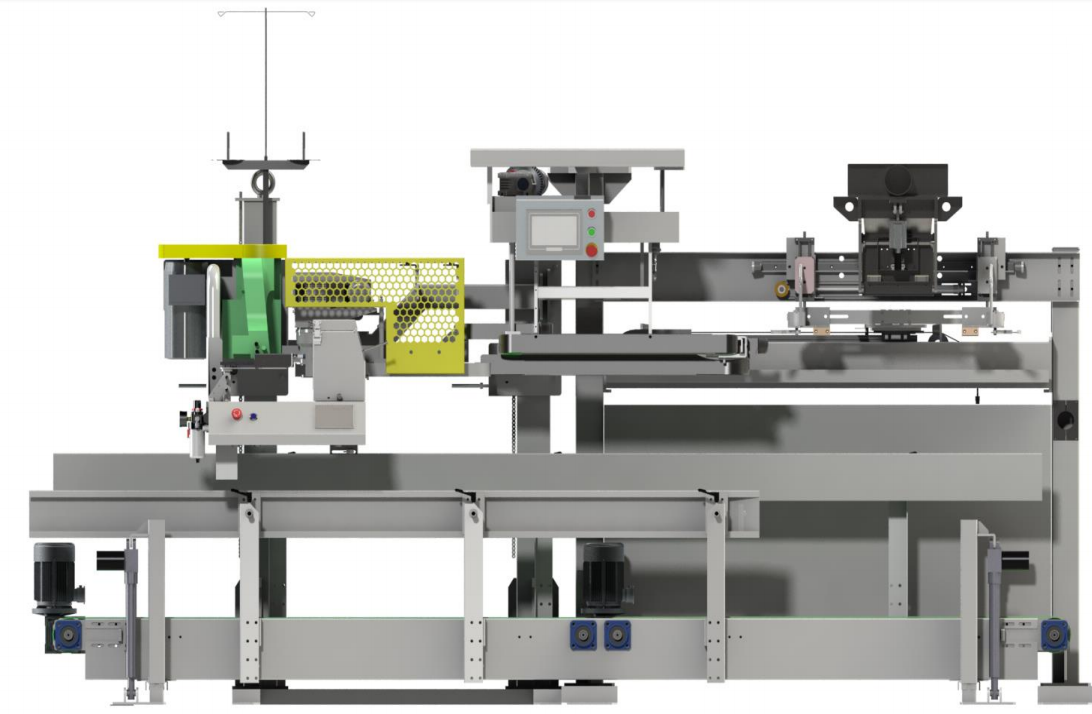

Fully Automatic Bagging Machine Grain Weighing Auto Bag Filling Machine

Technical Features:

1. The system can be applied to paper bags, woven bags, plastic bags and other packaging materials. It is widely used in chemical industry, feed, grain and other industries.

2. It can be packed in bags of 10kg-20kg, with a maximum capacity of 600 bags/hour.

3. Automatic bag feeding device adapts to high-speed continuous operation.

4. Each executive unit is equipped with control and safety devices to realize automatic and continuous operation.

5. Using SEW motor drive device can bring higher efficiency into play.

6. It is suggested that KS series heat sealing machine should be matched to ensure that the bag mouth is beautiful, leakproof and airtight.

Technical parameters:

| Serial number | Model | DCS-5U | |

| 1 | Maximum packaging capacity | 600 bags/hour (depending on material) | |

| 2 | fill style | 1 hair/1 bag filling | |

| 3 | Packaging materials | Grain | |

| 4 | Filling weight | 10-20Kg/bag | |

| 5 | Packaging Bag Material | Plastic bag

(film thickness 0.18-0.25 mm) |

|

| 6 | Packing Bag Size | long(mm) | 580~640 |

| wide(mm) | 300~420 | ||

| Bottom width(mm) | 75 | ||

| 7 | Sealing style | Paper Bag: Sewing/Hot Melt Adhesive Tape/Wrinkled Paper

Plastic bags: thermosetting |

|

| 8 | Air consumption | 750 NL/min | |

| 9 | Total power | 3 Kw | |

| 10 | weight | 1,300 Kg | |

| 11 | Shape size (length * width * height) | 6,450×2,230×2,160 mm | |

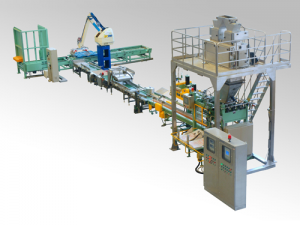

Workflow of automatic packaging machine:

1. Automatic Bag Feeder→

About 200 empty bags can be stored in two horizontally arranged bagging trays (the storage capacity varies according to the thickness of the empty bags). The sucker bagging device provides bags for the equipment. When the empty bags of one unit are taken out, the next unit’s disc is automatically switched to the position of taking out bags to ensure the continuous operation of the equipment.

2. Empty bag extraction→

Extraction of bags over automatic bag feeder

3. Empty bag open→

After the empty bag is moved to the lower opening position, the bag opening is opened by the vacuum sucker

4. Bag Feeding Device→

The empty bag is clamped at the lower opening by the bag clamping mechanism, and the feeding door is inserted into the bag to open the feeding.

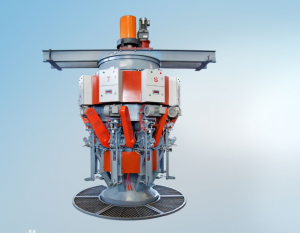

5. Transition hopper→

The hopper is the transitional part between the metering machine and the packing machine.

6. Bag bottom tapping device→

After filling, the device slaps the bottom of the bag to fully implement the material in the bag.

7. Horizontal movement of solid bag and clamping and guiding device of bag mouth→

The solid bag is put on the vertical bag conveyor from the lower opening, and is conveyed to the sealing part by the bag mouth clamping device.

8. Vertical bag conveyor→

The solid bag is conveyed downstream at a constant speed by the conveyor, and the height of the conveyor can be adjusted by the height adjusting handle.

9. Transition conveyor→

Perfect docking with equipment of different heights.

Mr. Yark

Whatsapp: +8618020515386

Mr. Alex

Whatsapp:+8613382200234