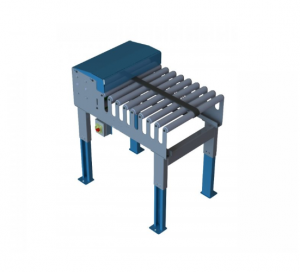

Industrial Filter Cartridge Dust Collector Equipment Dust Removal System

Brief Introduction

The dust collector can effectively reduce the dust content at the production site through the dust and gas isolation method, and can effectively increase the service life of the bag or filter cartridge through the pulse valve ,thereby reducing the maintenance cost.

Advantages

1. It is suitable for dust with high purification density and particle size greater than 5 m, but not for dust with strong adhesion;

2. No moving parts, easy to manage and maintain;

3. Small volume, simple structure and low price for the same air volume;

4. It is convenient to use multiple units in parallel when dealing with large air volume, and the efficiency resistance is not affected;

5. It can withstand high temperature of 400, if the use of special high-temperature materials, but also can withstand higher temperature;

6. After the dust collector is equipped with an abrasion resistant lining, it can be used to purify the flue gas containing highly abrasive dust.

7. It can be dry cleaning, is conducive to the recovery of valuable dust

Technical parameters

| Model | Bag Qty. | Filter area | Air volume

(m³/h) |

Weight

(kg) |

||

| 1m

(m²) |

1.5m

(m²) |

2m

(m²) |

||||

| TBLMF4 | 4 | 1.6 | 2.5 | 3.3 | 800-1200 | 200 |

| TBLMF6 | 6 | 2.5 | 3.7 | 5 | 1200-1500 | 240 |

| TBLMF9 | 9 | 3.7 | 5.5 | 7.4 | 1900-2500 | 300 |

| TBLMF12 | 12 | 5 | 7.3 | 9.9 | 2200-3000 | 380 |

| TBLMF15 | 15 | 6.2 | 9.2 | 12.3 | 2500-3600 | 430 |

| TBLMF18 | 18 | 7.4 | 11 | 14.8 | 3150-4500 | 480 |

| TBLMF21 | 21 | 8.6 | 12.8 | 17.2 | 3500-5500 | 515 |

| TBLMF24 | 24 | 9.9 | 14.7 | 19.7 | 4220-6000 | 600 |

| TBLMF28 | 28 | 11.5 | 17.1 | 23 | 4500-7500 | 695 |

| TBLMF32 | 32 | 13.1 | 19.6 | 26.1 | 4780-8000 | 720 |

| TBLMF36 | 36 | 14.8 | 22 | 29.6 | 5800-8400 | 750 |

| TBLMF40 | 40 | 16.3 | 24.5 | 32.7 | 6800-9800 | 820 |

| TBLMF42 | 42 | 17.1 | 25.7 | 34.3 | 7000-11000 | 888 |

| TBLMF48 | 48 | 19.7 | 29.3 | 39.4 | 6400-10800 | 900 |

| TBLMF56 | 56 | 23 | 34.2 | 46 | 8400-12000 | 982 |

| TBLMF64 | 64 | 26.1 | 39.2 | 52.2 | 10500-16500 | 1100 |

| TBLMF72 | 72 | 29.4 | 44.1 | 58.8 | 11600-16800 | 1300 |

| TBLMF104 | 104 | 42.5 | 63.7 | 84.9 | 16500-23700 | 1500 |

Each size is equipped with a different length of the different types of dust bag

Such as

TBLMF4:

|

Filter bag length (M) |

Filter area (M2) |

Air volume (m3/h) |

| 1 | 1.6 | 800 |

| 1.5 | 2.5 | 1000 |

| 2 | 3.3 | 1200 |

Wuxi Jianlong Packaging Co., Ltd.

Wuxi Jianlong Packaging Co., Ltd. is a R & D and production enterprise specializing in solid material packaging solution. Our product portfolio includes bagging scales and feeders, open mouth bagging machines, valve bag fillers, jumbo bag filling machine, automatic packing palletizing plant, vacuum packaging equipment, robotic and conventional palletizers, stretch wrappers, conveyors,telescopic chute, flow meters, etc. Wuxi Jianlong has a group of engineers with strong technical strength and rich practical experience, which can help customers with one-stop service from solution design to product delivery, freeing workers from the heavy or unfriendly working environment, improving production efficiency, and will also create considerable economic returns for customers.

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatsapp:+8613382200234