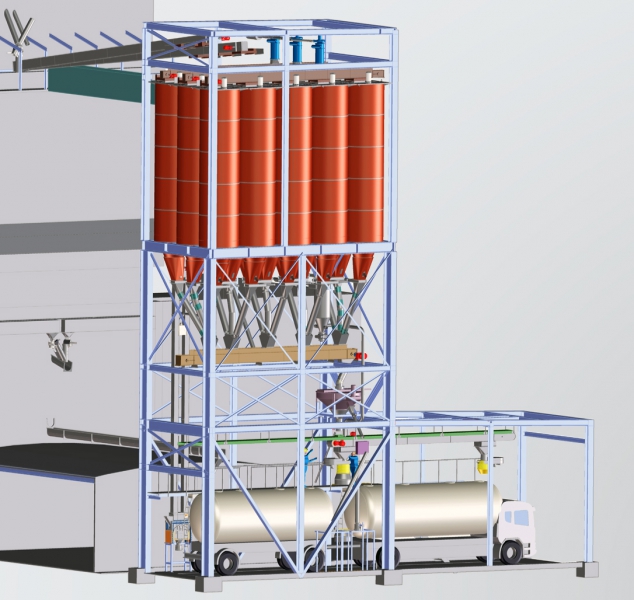

Industrial Material Loading Bellows Cement Bulk Machine Conveyor Belt Telescopic Chute

Product description:

JLSG series bulk materials telescopic chute, grain unloading tube is designed and made as per international standard. It adopts famous brand reducer, anti-exposure control cabin and could work reliable in high dust environment. This equipment is made with many good features including novel structure, high automated, high efficiency, lower working intensity, and dust-proof, environmental protection, etc. It’s widely used in grain, cement and other large bulk materials loading and unloading. It’s suitable for bulk materials train, truck loading, vessel loading and others.

For JLSG telescopic chute, single unit’s normal working capacity is 50t/h-1000t/h. And users must provide the required telescopic chute length.

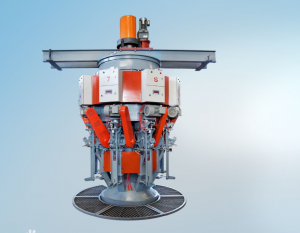

Components

Telescopic chute is mainly composed of power part, actuator, mechanical part and electrical part.

Power part: motor, reducer, spindle and other components; The actuator is mainly composed of wire rope and pulley, etc.

Mechanical part: by the top box, hose, tail shell, dust bag, etc.

Electrical part: sensor, material level switch, electrical cabinet and other components.

Features

1. Intelligent material level sensor, tracing material’s automatic lifting.

2. Manual-automatic operation.

3. High reliable control system

4. Provide electrical interlock control signal / operation status signal connection, easy for central control.

5. General / anti-exposure selection.

6. Telescopic chute length adjustable, less installation space.

Technical Parameters:

| Model | Loading capacity (T/H) | Power | Length | Air volume for dust collector |

| JLSG | 50-100 | 0.75-3KW | ≤7000mm | 1200 |

| JLSG | 200-300 | 2000 | ||

| JLSG | 400-500 | 2800 | ||

| JLSG | 600-1000 | 3500 |

Application

1. Grain and oil storage wharf, bulk feed, cement distribution and other industries

2. Suitable for train, tanker, bulk, such as loading vehicle.

Applicable materials: Cement, gravel, sand, rice, wheat, corn, soybean meal, soda, coke, feed and other powder, granular, block materials.

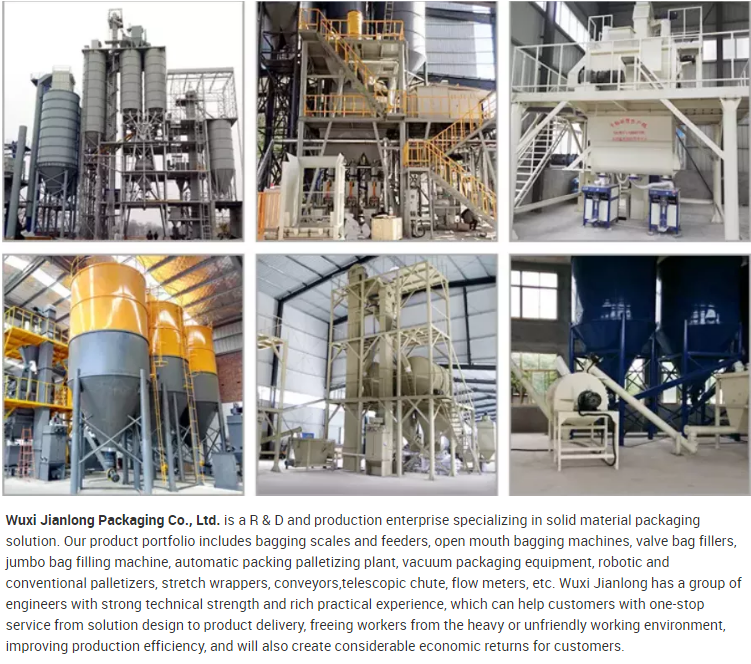

Other auxiliary equipment

Company profile

Mr. Yark

Whatsapp: +8618020515386

Mr. Alex

Whatsapp:+8613382200234