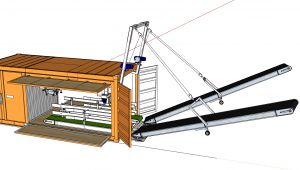

Mobile container bagging machine for port terminals

Description

Mobile container packing machines are a type of packaging equipment designed to be portable and easily transportable, usually housed in 2 containers or a modular unit. These machines are used to pack, fill or process products such as grain, cereals, fertilizers, sugar, etc. They are particularly useful in industries that require mobility and flexibility. They are widely used in locations such as port terminals and grain warehouses.

Technical Parameters

Model:Double containers double scales double lines

Weighing Range 25-50/50-100 kg (customized)

Accuracy ±0.2% FS

Packaging Capacity :2000-2400bag/hour

Voltage AC 380/220V 50Hz (customized)

Power 3.2-6.6 kw

Air Pressure 0.5-0.7 Mpa

Total Power:35KW

Bag Type: open mouth bag

(PP woven bag, PE bag, kraft paper bag, paper-plastic composite bag, aluminium foil bag, laminated poly woven bag)

Feeding Method: gravity feeding

Automatic Mode fully automatic / semi-automatic

According to the different production capacity and configuration requirements , we are happy to customize it within the customer's financial budget to meet the customer's needs to the greatest extent.

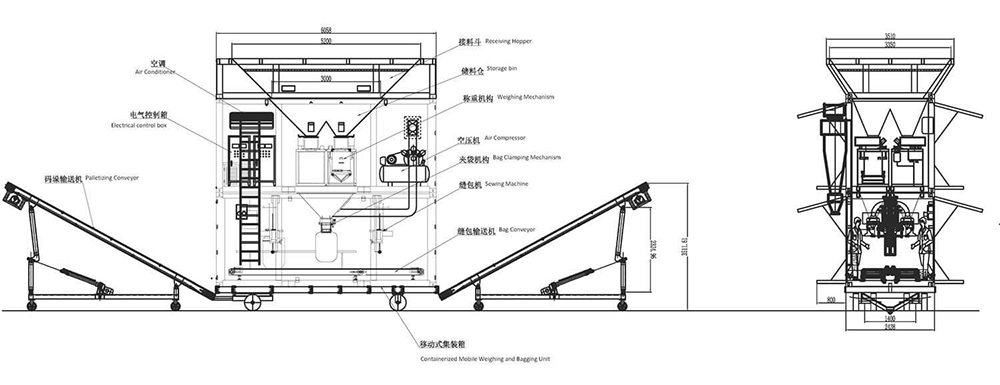

Drawing

Main components of electrical control system

The components are from renowned equipment provider such as OMRON, Schneider products and Siemens PLC

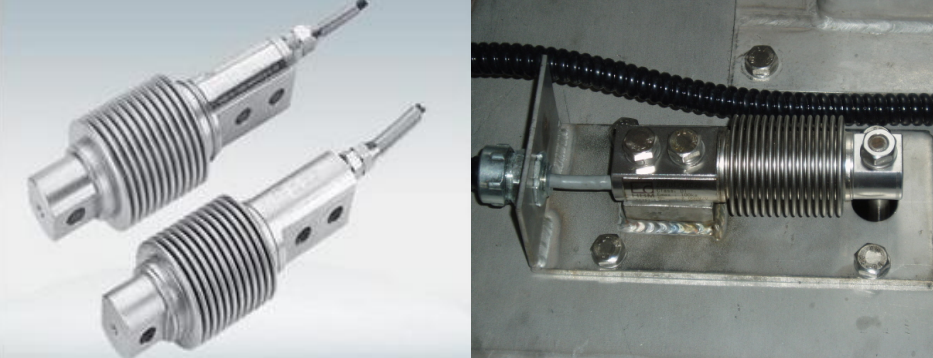

Load Cell

Force sensing structure with three-point sensor in weighing warehouse. And the center of gravity adaptive design, in order to ensure that the force can be fully transmitted to the gravity sensors and are be equipped with sealing protection device. The weighing sensor is made by HBM or ZEMIC

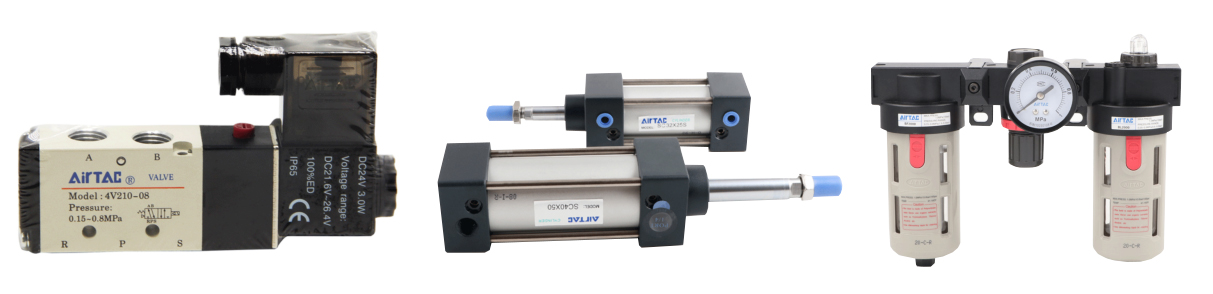

Pneumatic Control System

Consists of air compressor, gas pressure tester, oil cup, water filter, cylinder and solenoid valve. Solenoid valve is made by SMC ,AIRTAC

Newlong sewing machine DS-9C

High Speed Bag Closing Machine Head with mechanically operated cutter (Single Needle, Double Thread Chain Stitch Machine).

| Specifications | |

| Max Speed | 2,700rpm |

| Seam | Double Thread Chain Stitch |

| Stich Width | 7-10.5mm |

| Bag Material | Paper.PP |

| Thickness | Paper Bag 4P With a Tuck |

| Cutter | Automatic Crepe Tape Cutter |

| Needle | DR-H30 #26 |

| Oiling | Oil Bath |

| Oil | Tellus #32 |

| Weight | 41.0Kg |

| Feature | Crepe Tape Cutter |

Ingersoll Rand air compressor

Model:S10K7

Power:5.6KW

Capacity:700L/min

Cooling method: air cooling

Pressure:0.86 Mpa

Power supply:380V 50Hz 3P

Size:1550*600*900mm

Protection level:IP 54

Lorry loading conveyor

Product parameters

|

No. |

Name |

Specification |

|

1 |

Belt |

Rubber belt |

|

2 |

Machine shelf |

Carbon steel |

|

3 |

Length |

6500mm |

|

4 |

Width of belt |

600mm |

|

5 |

Lifting height |

3500mm |

|

6 |

Driving mode |

Electric linear actuator |

|

7 |

Main motor |

2.2KW |

Applicable Materials

Key Features

Portability:

The machine is mounted inside 2 standard shipping containers or a modular frame, making it easy to transport via trucks, ships, or trains.

It can be moved to different locations as needed, such as between port terminals, warehouses, or temporary job sites.

Containerized Design:

The entire system is self-contained within the container, which protects the machinery from environmental factors like dust, moisture, and temperature fluctuations.

The container can be customized to include power supplies, control systems, and other necessary infrastructure.

Flexibility:

These machines can be used for a variety of packing tasks, such as filling bags, boxes, or containers with products like grains, granulated fertilizers, sugar ect.

Quick Setup:

Mobile containerized packing machines are designed for rapid deployment. Once delivered to a site, they can be quickly set up and operational with minimal installation time.

Self-Sufficient:

Many units come equipped with their own power generators, air compressors, and control systems, allowing them to operate independently of local infrastructure.

Options

Hydraulic clamshell grab (10m³)

10M³ hydraulic clamshell grab (Option)

1.Bucket volume: 10 m³;

2.Volume weight: ~1t/m ;

3.Pulley diameter: Φ600mm;

4.Wire rope diameter: Φ28mm;

5.Maximum opening:4050mm;

6.Winding length / cable length:10-15m;

7.Dead weight: ~9t/m

Diesel Generator