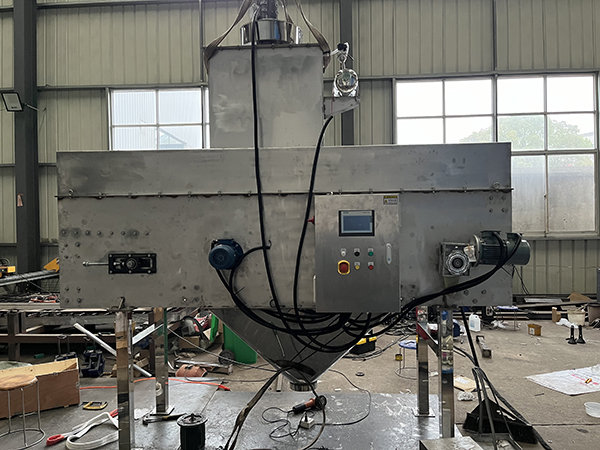

One-Cut Bag Slitting Machine , automatic bag opener and emptying system

The One Cut Type Bag Slitting Machine is an advanced and efficient solution designed for the automatic opening and emptying of material bags in industrial applications. This machine streamlines the bag slitting process, ensuring minimal material loss and high operational efficiency. It is ideal for industries handling bulk materials such as chemicals, food processing, pharmaceuticals, and construction materials.

Functionality

The operation of the One Cut Type Bag Slitting Machine is fully automated, reducing manual labor and increasing productivity. The process follows these steps:

1、Bag Loading: Workers place the material bags onto the belt infeeding conveyor.

2、Bag Conveyance: The chain conveyor transports the bags towards the slitting section.

3、Slitting Process: An alloy blade precisely slits the bag, ensuring a clean and efficient cut.

4、Material Discharge: The contents of the bag fall into the hopper by gravity, ensuring complete emptying.

5、Bag Removal: The empty slit bag is conveyed further by the chain and rolled out by the rolling machine for disposal or recycling.

Key Features

1、Efficient Single-Cut Unpacking: Throughout the entire unpacking process, the material bag requires only a single cut using a knife. This design ensures that the material inside and the packaging bag are completely separated, minimizing the risk of contamination. Additionally, because the bag is only cut once, there is almost no residual debris from the packaging material, leading to a cleaner and more efficient operation.

2、External Dust Removal for Minimal Dust Leakage: The system is designed with an external dust removal mechanism, which significantly reduces the amount of dust leakage during the unpacking process. This feature improves workplace safety, maintains cleaner working conditions, and enhances air quality by preventing excessive dust dispersion.

3、High Emptying Efficiency (99.00% - 99.99%): The equipment ensures an exceptionally high material emptying rate, ranging between approximately 99.00% and 99.99%. This high-efficiency emptying process minimizes material waste, maximizes resource utilization, and contributes to cost-effectiveness in industrial applications.

4、Compact and Suitable for High Dust-Control Environments: The system is specifically designed for use in environments with limited space and strict dust control requirements. Its compact structure allows for easy installation in confined areas, while its advanced dust control capabilities make it an ideal choice for industries that require high levels of cleanliness and air quality management.

Technical Parameters:

1.Capacity:

The machine is capable of handling 200 to 500 bags per hour, ensuring high operational efficiency and throughput.

2.Emptying Rate:

The system achieves an emptying efficiency of 99.00% - 99.99%, meaning that almost all material from the bags is successfully discharged, minimizing waste and material loss.

3.The equipment operates at a power rating of 8 kW, ensuring an optimal balance between performance and energy efficiency.

4.The system is designed to run on 380V, 50Hz, 3-phase (3P) electrical supply, which is a standard industrial voltage, ensuring compatibility with common power grids.

5.The integrated dust removal system has an air volume capacity of 1500 to 2000M³/hour , helping to maintain a clean working environment by effectively capturing dust and airborne particles.

These parameters ensure that the equipment operates efficiently, with high material recovery, reliable power supply, and effective dust control for a safe and productive working environment.