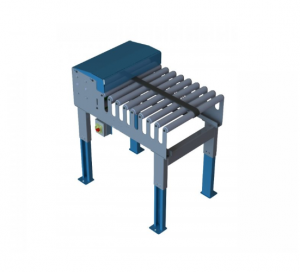

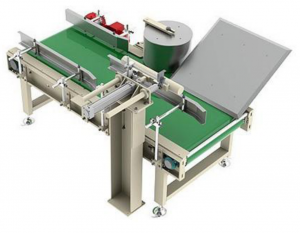

Roller Chain Pallet Conveyor Turntable Truck Loading Conveyor

Brief introduction

The robot pick up conveyor is used for positioning the material bag, and facilitate the palletizing robot can accurately locate and grip the material bag. The roller conveyor also named gravity conveyor, gravity roller conveyor, usually adopts the steel conveyor rollers to installed within a certain frame to transfer workpiece on the surface. One of the most used type is power roller conveyor, also called drive roller conveyor, because it needs drive part to make the workpiece transferring on rollers. The drive roller conveyor’s biggest feature is drived by motor .

| Name | roller conveyor | Model | roller conveyor |

| Length(mm) | 90 degree | Overal width(mm) | 870 |

| Width(mm) | 750 | Hieght (mm) | 900 |

| Material | steel | Color | black |

| Motor power | 400w | Speed | 18m/min |

| Load capacity | 200kg | Type | motorized conveyor |

| Warranty | 12 months | OEM | Yes |

About us

Wuxi Jianlong Packaging Co., Ltd. is a R & D and production enterprise specializing in solid material packaging solution. Our product portfolio includes bagging scales and feeders, open mouth bagging machines, valve bag fillers, jumbo bag filling machine, automatic packing palletizing plant, vacuum packaging equipment, robotic and conventional palletizers, stretch wrappers, conveyors,telescopic chute, flow meters, etc. Wuxi Jianlong has a group of engineers with strong technical strength and rich practical experience, which can help customers with one-stop service from solution design to product delivery, freeing workers from the heavy or unfriendly working environment, improving production efficiency, and will also create considerable economic returns for customers.

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatsapp:+8613382200234