Semi Automatic Wheat Flour Packaging Sugar Packing Machine Powder Bagging Machines

Brief Introduction:

DCS-SF2 Powder bagging equipment is suitable for powder materials such as chemical raw materials, food, feed, plastics additives, building materials, pesticides, fertilizers, condiments, soups, laundry powder, desiccants, monosodium glutamate, sugar, soybean powder, etc. The semi-automatic powder packaging machine is mainly equipped with weighing mechanism, feeding mechanism, machine frame, control system, conveyor and sewing machine.

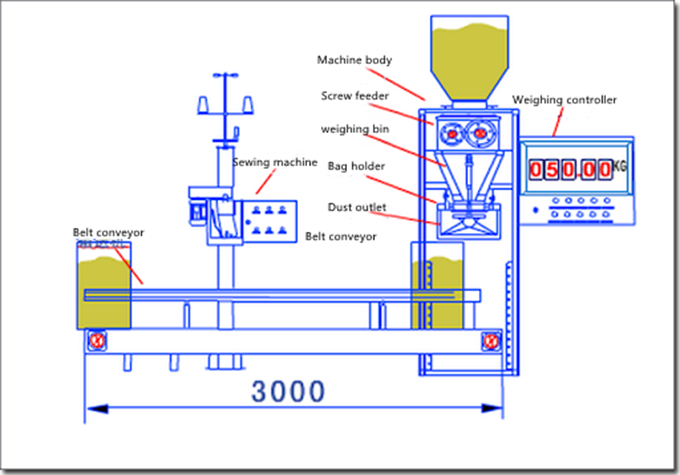

Structure:

The unit consists of the ration automatic packing scale and the selecting and matching parts: conveyer and the hemming machine. It uses spiral to feed the material, and the feed gearing is suitable for a comparatively worse fluidity of powdery material. The material is discharged forcefully by the feed gearing. The main component parts are feeder, weighing box, clamping box, the computer control, pneumatic actuator.

Application

DCS series screw feeder packing machines are used to weighing and packing powdery materials such as flour, starch, cement, premix feed, lime powder etc. The weight from 10kg-50kg is available.

The bag can be closed by heat sealing for lining/plastic bags and sewing (thread stitching) for woven bags, paper bags, kraft bags, sacks etc.

Main Using:

It is suitable for rationing package of the powdery material in the feed, food, grain, chemical industry or particulate material. (For example: the grainy material in the mixture, premix material and concentrated material, starch, chemical powder material etc.)

Technical Parameter:

| Model | DCS-SF | DCS-SF1 | DCS-SF2 |

| Weighing Range | 1-5, 5-10, 10-25, 25-50 Kg/bag, customized needs | ||

| Precisions | ±0.2%FS | ||

| Packing Capacity | 150-200bag/hour | 250-300bag/hour | 480-600bag/hour |

| Power supply | 220V/380V, 50HZ, 1P/3P (Customized) | ||

| Power (KW) | 3.2 | 4 | 6.6 |

| Dimension (LxWxH)mm | 3000x1050x2800 | 3000x1050x3400 | 4000x2200x4570 |

| The size can be customized according to your site. | |||

| Weight | 700kg | 800kg | 1000kg |

Features:

* Automatic and Manual mode.

* Designed to suit open mouth bags.

* Multiple product types can be bagged.

* Easy to clean, easy to maintain.

* System can accommodate different bag sizes using bolt-on fittings.

* Easy integration with a conveyor.

* Can be designed as a free-standing (as shown at left) or bolt on to existing supply bin arrangement.

* Up to 100 different product target weights can be stored and recalled using the digital indicator.

* Product in-flight is taken into account.

* Units are built to Customer’s requirements, including bin sizes, bin finishes (painted or stainless steel), mounting frame, discharge arrangement, etc.

Details

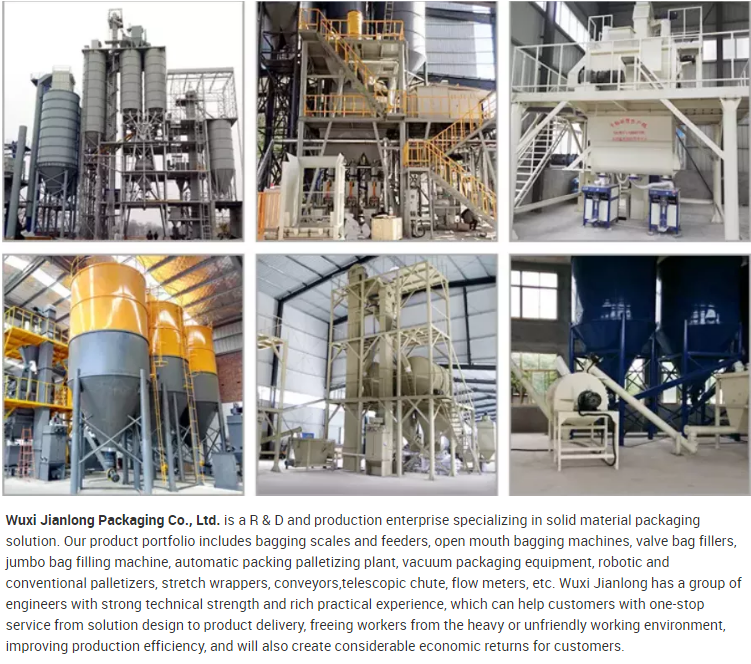

About us

Mr. Yark

Whatsapp: +8618020515386

Mr. Alex

Whatsapp:+8613382200234