Industrial Vacuum Conveyor Systems | Dust-Free Material Handling Solutions

Vacuum feeder, also known as vacuum conveyor, is a kind of dust-free closed pipeline conveying equipment that uses micro vacuum suction to convey particles and powder materials. It uses the pressure difference between the vacuum and the ambient space to form a air flow in the pipeline and move the material , thereby completing the material transportation.

What is a Vacuum Conveyor?

A vacuum conveyor system (or pneumatic conveyor) uses negative pressure to transport powders, granules, and bulk materials efficiently. Ideal for industries requiring contamination-free handling, these systems replace manual labor with automated, closed-loop processes. From food-grade stainless steel designs to explosion-proof setups for hazardous environments, vacuum conveyors ensure precise, gentle, and compliant material transfer.

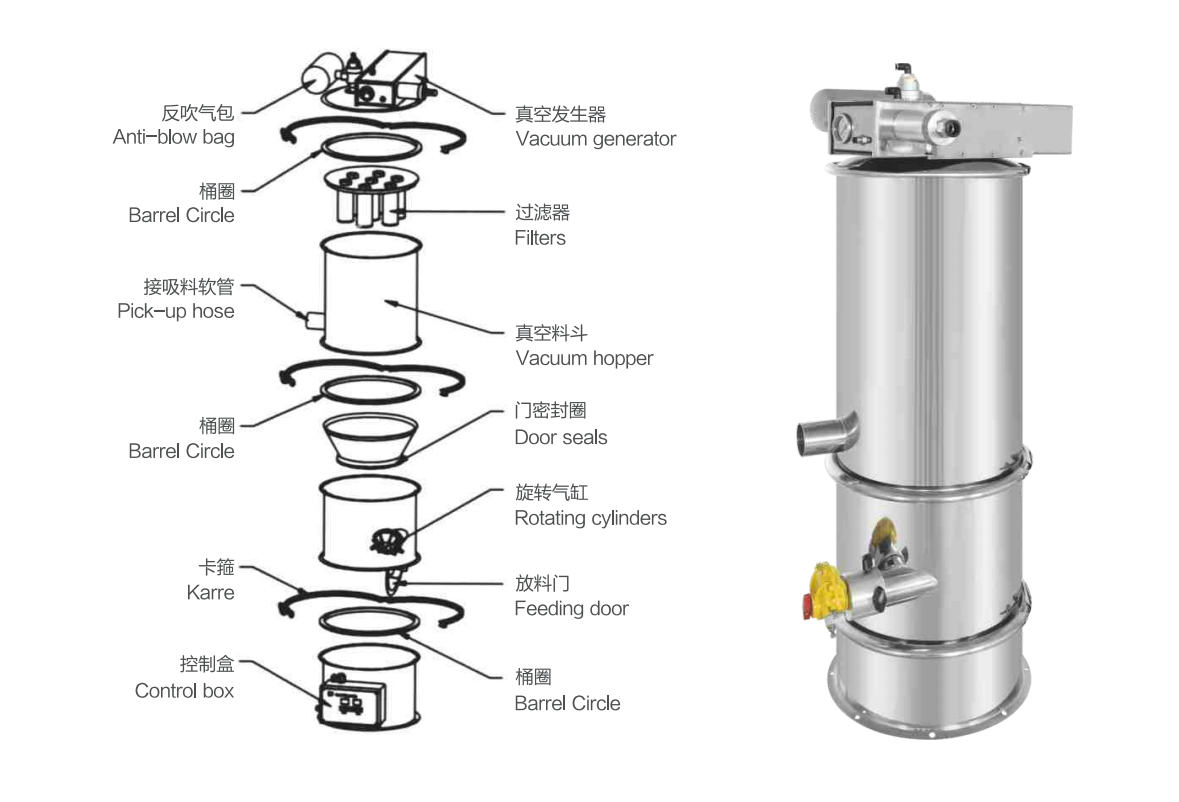

Key Components & Advanced Technology

Modern vacuum conveyors integrate cutting-edge engineering for reliability:

- Vacuum Generators: Rotary vane pumps, Venturi ejectors, or energy-efficient PIAB vacuum pumps.

- Dust-Tight Filtration: HEPA filters and pulse-jet cleaning systems prevent particle emissions.

- Smart Controls: PLC-driven automation with touchscreen interfaces for batch or continuous operation.

- Safety Compliance: ATEX-certified motors, anti-static tubing, and explosion-proof designs.

- Hygienic Construction: CIP/SIP-compatible stainless steel for FDA, GMP, and ISO standards.

Top Applications Across Industries

Vacuum conveyors solve critical challenges in:

- Pharmaceuticals

- Transfer APIs, excipients, and sensitive powders with zero cross-contamination.

- Sanitary designs meet GMP and containment requirements.

- Food & Beverage

- Handle spices, flour, sugar, and additives in FDA-compliant stainless steel systems.

- Chemicals & Plastics

- Safely convey abrasive, explosive, or hygroscopic materials using ATEX-certified components.

- 3D Printing & Additive Manufacturing

- Transport metal powders (e.g., titanium) and polymers without segregation.

- Agriculture

- Efficiently load/unload grains, seeds, and fertilizers with minimal waste.

Why Choose a Vacuum Conveyor Over Mechanical Systems?

- Gentle Handling: Preserve fragile materials like plastic pellets or cohesive powders.

- Closed-Loop Design: Eliminate dust, reduce OSHA risks, and ensure worker safety.

- Energy Efficiency: Optimize power use with lean-phase or dense-phase conveying modes.

- Low Maintenance: Self-cleaning filters and minimal moving parts cut downtime.

- Scalability: Customize systems for batch processing or high-volume continuous lines.

Compliance & Safety Features

- ATEX/IECEx Certification: Safe operation in explosive atmospheres (e.g., chemical dust).

- FDA & USDA Compliance: Hygienic surfaces and sanitary welds for food/pharma.

- OSHA Alignment: Dust containment protects workers and avoids regulatory penalties.

Choosing the Right Vacuum Conveyor

Ask these questions when selecting a system:

- Material Type: Is it abrasive, explosive, or prone to static?

- Industry Standards: Do you need GMP, ISO, or CIP/SIP compatibility?

- Capacity: Batch processing or continuous high-volume transfer?

- Budget: Balance upfront costs with long-term energy savings (e.g., PIAB vacuum pumps reduce energy use by 50% vs. traditional systems).

Contact:

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatapp:+8613382200234

At Wuxi Jianlong, we engineer industrial vacuum conveyor systems that redefine efficiency and safety in material handling. Designed for industries requiring contamination-free transport of powders, granules, and bulk materials, our systems combine cutting-edge technology with industry-specific compliance. Whether you operate in pharmaceuticals, food processing, or hazardous chemical environments, our vacuum conveyors deliver unmatched reliability and precision.

1. Advanced Technology for Unmatched Performance

- Powerful Vacuum Generation: Equipped with energy-efficient rotary vane pumps or Venturi ejectors, ensuring rapid material transfer with minimal energy consumption.

- Smart Automation: PLC-controlled systems with intuitive touchscreen interfaces for seamless batch or continuous operation.

- Dust-Tight Filtration: HEPA filters and pulse-jet cleaning mechanisms eliminate airborne particles, meeting OSHA and EPA standards.

2. Industry-Specific Solutions

- Pharmaceutical & Nutraceutical: GMP-compliant, stainless steel conveyors with CIP/SIP compatibility for APIs and sensitive powders.

- Food & Beverage: FDA/USDA-approved designs for hygienic handling of spices, flour, sugar, and additives.

- Chemicals & Plastics: ATEX-certified, explosion-proof systems for flammable or abrasive materials.

- 3D Printing & Manufacturing: Gentle handling of metal powders (e.g., titanium) and polymers to prevent segregation.

3. Safety & Compliance Guaranteed

- Explosion-Proof Certification: ATEX/IECEx-compliant components for hazardous environments.

- Hygienic Construction: Smooth surfaces, sanitary welds, and easy-clean designs to prevent bacterial growth.

- Global Standards: Adherence to FDA, ISO 9001, and OSHA regulations for risk-free operations.

- Gentle Material Handling: Preserve product integrity of fragile pellets, cohesive powders, or hygroscopic materials.

- Closed-Loop Systems: Zero dust emission, ensuring worker safety and reduced cleanup costs.

- Low Maintenance Design: Self-cleaning filters and robust components minimize downtime.

- Scalable Configurations: Customizable for small-batch processing or high-capacity production lines.

- Pharmaceuticals: Transfer APIs, excipients, and tablet granules in contained environments.

- Food Processing: Efficiently load mixers, blenders, or packaging machines with food-grade safety.

- Chemical Manufacturing: Safely convey corrosive powders or explosive materials.

- Agriculture: Streamline grain, seed, and fertilizer handling with minimal waste.

- Capacity: 500 kg/hr to 20,000 kg/hr (customizable).

- Materials of Construction: 304/316L stainless steel, anti-static polymers.

- Power Options: Electric, pneumatic, or hybrid systems.

- Certifications: ATEX, FDA, GMP, ISO 9001.

-

Optimized for Your Workflow

Pair our vacuum conveyors with complementary equipment like bagging machines, silos, or mixers for a fully automated production line. Our engineers provide end-to-end support—from system design to installation and maintenance.

-

Why Partner with Wuxi Jianlong?

- 50+ Years of Expertise: Trusted by leading global brands in material handling.

- Custom Engineering: Tailor-made systems to match your workflow and budget.

- Lifetime Support: Comprehensive maintenance plans and 24/7 technical assistance.

Ready to Upgrade Your Material Handling Process?

Contact BaggerMachine today to schedule a consultation or request a demo. Let us help you achieve dust-free, efficient, and compliant operations!