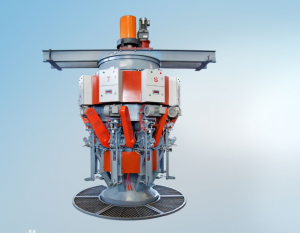

Volumetric Semi Auto Bagging Machines Manufacturers Automatic Bagger

Function:

The semi automatic volumetric metering and packaging system adopts the form of manual bagging and three speed gravity feeding, which is controlled by the intelligent electric control system to automatically complete the processes of feeding, weighing, bag clamping and feeding. It adopts the computerized weighing controller and weighing sensor to make it have superior zero stability and gain stability. The machine has the functions of coarse and fine feeding setting value, single bag weight setting value, bag counting, weight cumulative display, automatic peeling, automatic zero adjustment, automatic error correction, out of tolerance alarm and fault self diagnosis. The communication interface can be configured according to the needs of users. The part in contact with materials is made of 304 stainless steel.

Application:

peat soil, seedling substrate,compost,organic fertilizer, ceramsite and other granular and powder materials.

Main features:

1. Good integrity: small floor area, flexible and convenient installation.

2. Adjustable speed: the auger conveys the material, which is controlled by the instrument, and the feeding speed can be set arbitrarily.

3. High accuracy: volume weighing.

4. Environmental protection operation: closed internal circulation system can effectively prevent dust from flying, improve working environment and protect employees’ health.

5. Reasonable structure: compact structure, small volume, can be made into fixed or mobile body according to customer requirements.

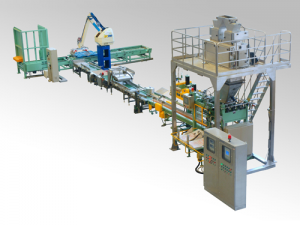

Technical parameters:

| No. | Name | Item | Parameter |

|

1 |

Volumetric packing machine |

Volume(L/Bag) | 20-50 |

| Capacity(bag/min) | 3-6 | ||

| Accuracy | +/-0.2% | ||

| Power(kw) | 1.5 | ||

| Air | 0.4-0.8 Mpa, 0.1 m/min | ||

| Weight(kg) | 360 | ||

| 2 | Weighing controller | AMP | |

| 3 | Weighing sensor | Keli | |

| 4 | Electrical components | Schneider | |

| 5 | Pneumatic components | AIRTAC | |

| 6 | Bag clamper | Weight(kg) | 60 |

|

7 |

Belt conveyor |

Length(mm) | 3000 |

| Power(kw) | 0.37 | ||

| Weight(kg) | 120 | ||

| 8 | Sewing machine | Power(kw) | 0.37 KW |

| Thread cutting mode | Pneumatical | ||

| 9 | Size | L*W*H(mm) | 3000*1100*2200 |

| Weight(kg) | 530 | ||

Mr.Yark

Whatsapp: +8618020515386

Mr.Alex

Whatsapp:+8613382200234